Digital twin technology enables companies to create simulations that predict an object or process performance using the physical world’s data in real-time.

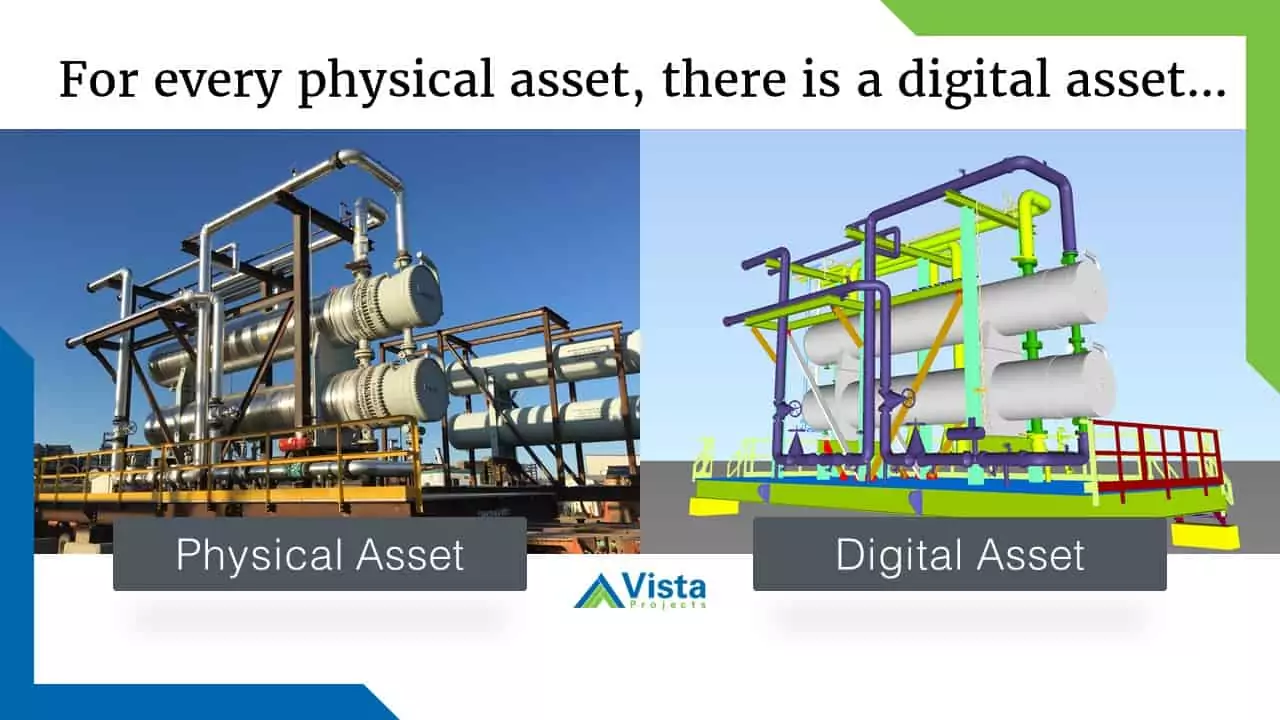

Essentially, a digital twinA digital twin is a precise, virtual representation of a physical object system, process, or asset. Digital twins integrate machine learnin… is a virtual representation of the physical world. It forms the bridge between the physical and digital objects. As we say at Vista, for every physical asset, there exists a digital asset.

The Origins of Digital Twins

The idea first sparked at NASA in the 1960s where mock-ups of space capsules paved the way to digital simulations. NASA in fact used digital twin technology in assessing and simulating the conditions of Apollo 13.

Michael Grieves first used the term “digital twin technology” in 2002 at the University of Michigan.

“Only when we get it to where it performs to our requirements do we physically manufacture it. We then want that physical build to tie back to its digital twin through sensors so that the digital twin contains all the information that we could have by inspecting the physical build.”

A digital twin consists of the physical object, virtual object, and the interlinking connection of the two which is the data from the physical to the virtual object.

The technology was further subdivided by Grieves and Vickers into:

- Digital Twin Prototype (DTP) – contains all the information (designs, analysis, processes) needed to build a physical product. It is however not linked to any physical product.

- Digital Twin Instance (DTI) – contains links to a specified asset containing information about it.

- Digital Twin Aggregate (DTA) –an aggregate of DTIs.

- Digital Twin Environment (DTE) – an integrated, multi-domain physics application space for operating on digital twins mainly in predictive and interrogative analysis.

Digital twins can be distinguished from other technologies by their characteristics:

- Connectivity – the technology enables inter-linking between physical and digital components created by sensors obtaining, integrating, and transmitting data in the physical product.

- Digital technology – digital twin is an enabler of data homogenization where virtualized objects can be decoupled from their physical nature.

- Unconstrained information/data sharing – gathered data can be shared without time or location restriction easily.

- Reprogrammable – with artificial intelligence, collected data can be used to make necessary adjustments on a physical object for instance in jet engines autopilot modes.

- Digital traces – it’s possible to identify where an error occurred during a diagnosis problem as the twin technology keeps traces.

- Modularity – with digital twins, physical objects can be designed and customized as it enables tracking of possible adjustments in a machine.

Rooted in Data Science & Applied Math

Digital twin technology is rooted in data science and applied mathematics. This is where research on the physics underlying a physical asset or object is copied and used to develop mathematical models which virtualize the physical world.

The twin technology is developed to gather data from sensors in real-time hence allowing the simulation of physical objects offering insights into performance potential mishaps in real-time. This distinguishes digital twin technology from normal simulations as the latter is static while the digital twin is dynamic.

In essence, a company creates digital twins to capture changes on the physical object and have them directly reflected on the virtual model.

Although there isn’t yet a standardized digital twin technology platform, several companies offer solutions to capturing and managing the data. While industrial companies, like GE, see the direct business benefits of digital twins, technology companies like Microsoft and Amazon Web Services are well suited to process big data.

The digital twin design comprises:

Data Collection

Through the use of sensors, day-to-day operations, product information, and any other data source, information is gathered. The data could include behavioral means of systems, physical scans of materials, etc.

Model Creation

The collected data is used to create virtual models that can be analyzed through the use of machine learning, artificial intelligence. Created models can be displayed via AR (augmented realityaugmented reality (AR) is the superimposition of digital data, usually an image, onto real-world objects to enhance the user’s understandi…) or VR (virtual reality) and then used in the predictive and interrogative analysis.

Inter-linking

Once the analysis is complete, the results are used in developing a physical twin.

Applications of Digital Twins

Digital twin technology is substantial to the development of Industry 4.0 in the providence of automation, combined manufacturing processes, and de-risking product rollouts.

In a Gartner survey, 13% of respondents indicated they have digital twins in use while 62% are planning to. Gartner VP, Benoit Lheureux, estimates that over two-thirds of companies using the internet of things (IoT) will have at least some digital twin technology in production by 2022.

As of today, digital twins can be applied to several sectors thanks to cloud-based storage, VR, NLP (Natural Language Processing), AR, computer vision, and AI.

Oil and Gas Sector

With the constant volatility in global energy commodities, asset owners are digitally transforming their supply chain to reduce the total cost of ownershipThe total cost of ownership refers to the total cost of owning an industrial asset throughout its full lifecycle, from design and construc….

Plant operations can be streamlined through the use of digital twins. This tactic is especially useful when the digital twin approach begins at the onset of engineering.

At Vista Projects, we help clients simplify the digital transformation of their assets. We do it by hosting a digital twin of the asset in a technical data portalA technical data portal (also known as digital project hub) is a web-based application that allows users to organize, validate and collabo… that provides all project stakeholders a single source of truth about the asset.

Vehicle Production

Digital twins in manufacturing cover areas from business administration to production and supply functions. The manufacturers get a virtual mock-up of any product that can be evaluated or projected to final product functionality.

Formula 1 cars have been deployed with digital twin technology to help the manufacturers and drivers know of any necessary adjustments to improve their performance.

Digitized Cities

Digital twin technology also benefits the construction industry. In Singapore, for example, a digital twin was developed to help city planners improve energy consumption and provide better services for its citizens.

Health Care Sector

With AI models and sensors, data from sensors used in monitoring a patient can be used in developing digital twins models. The models can help the health care sector develop in improvements of a patient’s data care as clinical procedures can be applied on the digital models before trying it on a patient.

Other areas where digital twin technology can be applied include:

- human virtualization

- farming modernization

- smartphone testing

- construction sites

A perfect example of other digital twin applications is the GE digital wind farm which adopted digital twins to improve operating efficiency by 20%. GE analyses the data gathered from each turbine prior to the physical construction of the wind turbines.

According to the statement by their Chief Digital Officer, Ganesh Bell, “For every physical asset in the world, we have a virtual copy running in the cloud that gets richer with every second of operational data.” This is an indication of digital twin take over as more companies venture into it for their competitive advantages.

Other Areas

Other areas where digital twin technology can be applied include:

- human virtualization

- farming modernization

- smartphone testing

- construction sites

- emerging energy

A perfect example of other digital twin applications is the GE digital wind farm which adopted digital twins to improve operating efficiency by 20%.

GE analyses the data gathered from each turbine prior to the physical construction of the wind turbines. According to their Chief Digital Officer, Ganesh Bell:

For every physical asset in the world, we have a virtual copy running in the cloud that gets richer with every second of operational data.

It’s an indication of how digital twin technology will take over as more companies venture into it for their competitive advantages.

Advantages of Digital Twin Technology

Digital twin technology is vital to Industry 4.0 and digital transformation. Depending on the application, digital twins can be diversely beneficial.

- Reduction in maintenance cost as potential breakdowns can be predicted beforehand.

- Risks of accidents, market reputation, or product availability can be mitigated prior to occurrence.

- Improvement of product quality by analysis of customization models through real-time performance testing.

- Increased reliability in the production lines through monitoring to improve performance.

- Conceptual development as a digital twin allows prototyping which in turn reduces probabilities of product defects during production.

Get Help with Your Digital Twin

Digital transformation and digital twin technology are complex topics. For industrial sectors, the cost savings potential is huge but it’s easy to get lost in complexity.

From digitizing brownfield assets to helping new technologies get to market faster, this is the time to be investing in the efficiencies of digital execution. But it is also a time when most companies can’t afford to implement a system that doesn’t get used to its full potential.

At Vista, we have years of first-hand system integration experience and continue to advance our own project execution.

If you would like a cold eyes review of your implementation or help to maximize the return on your digital transformation investments, contact Vista Projects today to schedule a consultation.