System Integration Consultants

Digital Transformation

Solutions that Work for

Your Asset

We Simplify Digital Transformation

So You Can...

-

Get Real-Time Information

With the integrated information access portal, your project team has on-demand access to all the latest information about the asset.

-

Lower TIC & TCO

Lower the total installation cost and total cost of ownership of your asset with current data readily available to all stakeholders for its full lifecycle.

-

Make Informed Decisions

Instead of waiting on reports with weeks-old information, you can base important decisions on the latest data about your project or asset.

-

Automate Repeating Tasks

Schedule and automate repeating data flows and quality actions to save time and keep your team focused on high-value tasks.

We Do it With

Data-Centric Execution

Architecture

A comprehensive data-centric approach has huge cost savings potential for your asset.

The efficiencies go far beyond the installation cost of a single project. When properly implemented, the benefits of a single-source-of-truth project execution strategy will last for the lifecycle of your asset. With industrial facilities, the cost savings represent millions of dollars.

Can your organization afford to walk away from millions in savings ?

-

System Implementation

-

Engineering Design

-

Project Services

-

Operations

A turnkey approach to your

digital execution architecture

The goal is for your team to be able to confidently and consistently make data-driven decisions that benefit the entire organization. It’s possible when you have real-time information about your projects and assets.

We partner with you to structure your data in a single-source-of-truth environment, ensuring your team shares access to accurate and validated information. Backed by a unique mix of integrated engineeringThe process of integrated engineering involves multiple engineering disciplines working in conjunction with other project disciplines to e… and system implementation experience, Vista Projects is well equipped to properly configure your digital execution architecture:

- Establish the intelligent tools

- Complete system integrations between tools

- Develop a technical data portalA technical data portal (also known as digital project hub) is a web-based application that allows users to organize, validate and collabo… for all project stakeholders

- Identify solutions to potential issues with digital processes

- Enhance the quality of deliverables via data comparisons

Ensure proper integrations with your engineers, designers, vendors, and operators

We can help you achieve complete transparency between engineering disciplines and other project stakeholders via a single-source-of-truth environment. With years of experience working in digital engineering environments, we have the knowledge to efficiently implement your technical data portal.

By working with Vista Projects as your systems integration partner, you’ll be able to:

- Develop fit-for-purpose workflows for engineering and design within a digital environment

- Provide engineering and design services in a data-centric digital environment to ensure highly useful and searchable deliverables

- Leverage our lessons learned catalog to ensure the successful implementation of engineering tools that work for engineers

- Identify solutions to potential issues with digital processes

Empower your capital project teams with digitally-enabled tools and processes

The benefits of a digital execution strategy are not confined to your engineering team.

We can help implement a fit-for-purpose digital execution strategy for your entire capital project team or across your enterprise. With a properly configured system, you’ll enjoy centralized, on-demand access to:

- Project management key metrics

- Project cost controls data

- Materials management and tracking details

- Vendor data management

- Contracts management

Extend the benefits of a data-centric approach throughout the asset’s lifecycle

Deploying your digitally enabled system is just the start. Your data-centric approach to project execution extends beyond head-office employees to field and operations staff. We can help with training and site implementation to ensure there are no access issues and everyone takes full advantage of the new system.

Vista Projects offers the following services for operations staff.

- Information access audit

- Technical data portal implementation – a web-based application that allows users to organize, validate, and collaborate on asset data and documents regardless of their location

- Training for your field staff to ensure everyone knows how to take advantage of the tools

System Integration Partner

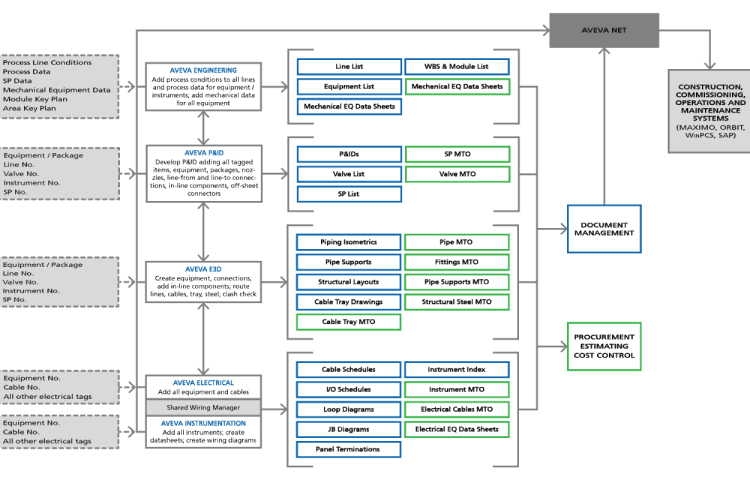

As an AVEVA Partner, Vista Projects specializes in the implementation, configuration, administration, and support of AVEVA’s Asset Information Management suite. We support both owners/operators and EPCs with capital project implementations. The union of our integrated engineering and technical expertise is a true advantage. Our team has the knowledge and experience to help you maximize the return on your software investments.

About Digital Engineering

Environments

Intro to Digitally Enabled Engineering

FAQ - System Integration

What is system integration?

System integration is about bringing together data processes and workflows from multiple sources or applications into a single system. There could be several tools and databases in the technology stack for an industrial project, and it’s essential for all these sources to be seamlessly integrated.

By combining these datasets, users are able to access data originating from many different applications or locations via a single interface. This typically makes information more robust and allows data to be accessed more efficiently.

What is a System Integrator (SI)?

System Integrators (SI) are teams of development specialists that are well versed in source data extraction, data transformation, data loading, and visualization. The SI’s job is to combine and validate all sources into a single integrated information access portal.

Vista has an experienced SI team that includes data scientists, system specialists, application specialists, designers, and engineers. The team’s collective skills have solved numerous integration problems for our clients.

How is Industry 4.0 defined?

Also known as the fourth industrial revolution, Industry 4.0 is the term used to describe the growing trends of automation, big data exchange, and intelligent networking in industrial manufacturing technologies.

Industry 4.0 is a core concept in the digital transformation of industrial assets and processes as traditional heavy industries increase their use of cyber-physical systems, the industrial internet of things (IIoT), cloud computingCloud computing is a method of delivering IT services where resources and data are retrieved from the Internet using web-based applications …, cognitive computing, and digital twins.

What does single source of truth mean?

Single source of truth (SSOT) refers to the practice of structuring information models and associated data schema such that every data element is stored exactly once.

Linkages to this data element are by reference only because all other locations of the data just reference back to the primary “source of truth” location. Any updates to the data element in the primary location propagate to the entire system without the possibility of a duplicate value somewhere being forgotten.

What is a digital twin?

A digital twinA digital twin is a precise, virtual representation of a physical object system, process, or asset. Digital twins integrate machine learnin… is a precise, virtual representation of a physical object system, process, or asset. Digital twins can integrate machine learning, artificial intelligence, and data analytics to create digital model simulations that help to predict potential issues with their real-world counterparts.

A common concept within the industrial internet of things (IoT), digital twins are used in the energy industry to optimize operations and maintenance of production facilities. This helps companies detect early signs of equipment failure and proactively respond, plan, and implement corrective maintenance actions at a considerably lower cost and safety risk.

What is digital transformation?

A Capgemini-MIT report defined digital transformation as “the use of technology to radically improve performance or reach of enterprises.”

Digital transformation goes beyond modernizing processes and using the cloud. It embraces the “future of culture,” enabling empathy and empowerment alongside innovation, artificial intelligence, and big data.

Put simply, digital transformation isn’t just about technology and processes. It’s also about people. Vista takes all these components into consideration and helps simplify the digital transformation of your asset.

Read more about the 3 main components of digital transformation or check out these digital transformation quotes.

All Clients Deserve

A Single Source of Truth

Our unique truth-based industrial engineering execution model facilitates:

- Transparency about projects and assets

- A collaborative problem-solving approach

- High-quality engineering designs

By structuring data in a single-source-of-truth (SSOT) environment, we simplify the digital transformation of your asset and help you make more informed decisions. Learn more about our system integration services.

What Our Clients Say

Improve your project success with the help of seasoned experts

Tyler Elchuk

Business Development Director

Related Articles

Sorry, we couldn't find any posts. Please try a different search.