Well Pad Design

Overview

Client

Project facility

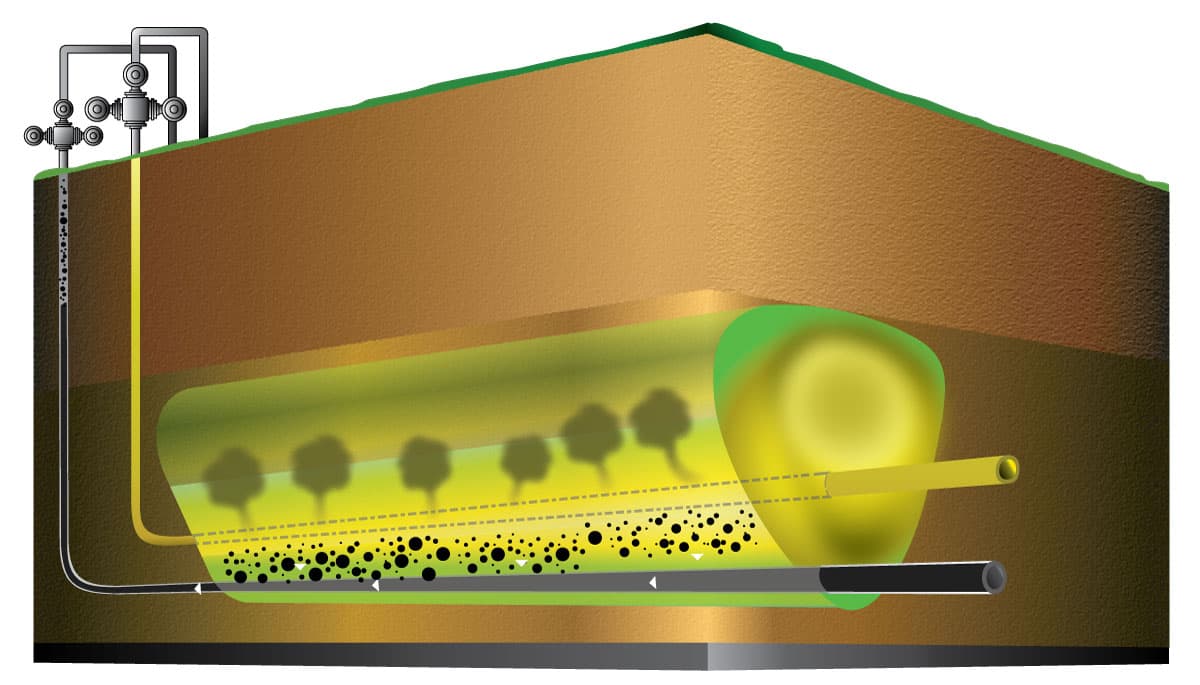

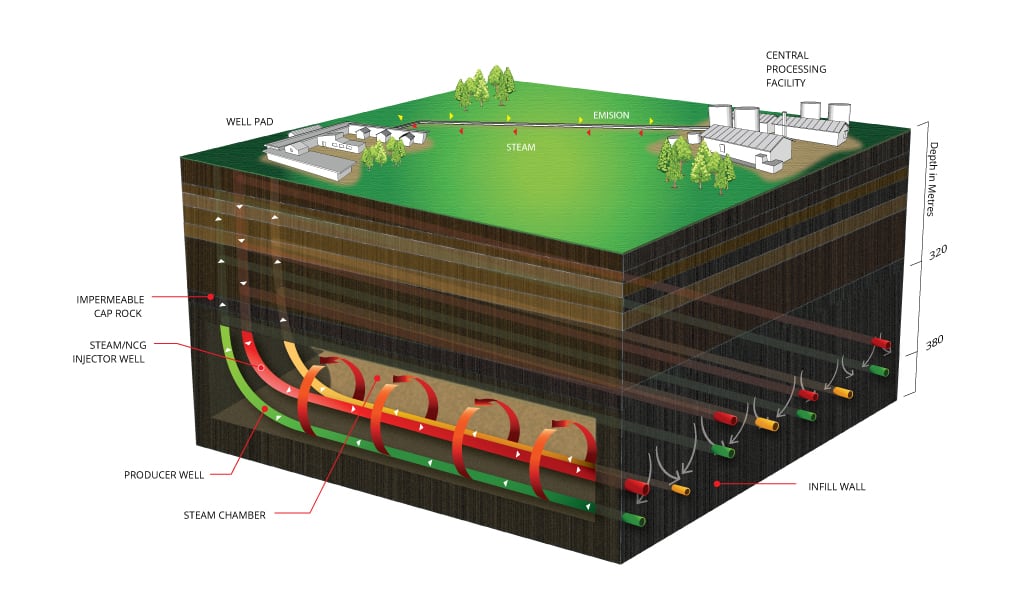

Christina Lake is a largescale processing facility that uses in-situ steam-assisted gravity drainage (SAGD) technology to extract bitumen.

Situation

As thermal in-situ assets are developed, they require new wells to be installed to sustain and grow production.

The significant quantity of new wells brought on-stream provides an opportunity to take advantage of economies of scale through standardization and transitioning from fabrication to manufacturing style processes.

Solution

Outcomes

The new well pad design resulted in a TIC savings of 40% compared to the previous generation well pad. A significant contributor to the cost reduction was field execution being shortened by several months.

Equipment & Technology

The well pad design was developed to intrinsically support the full lifecycle of operations, from steam circulation and production to end-of-cycle enhanced oil recovery technologies.

Our designs support natural and artificial lift technologies (gas lift, PCP, ESP, plunger, etc.).

Among other items, the design development includes:

• Group and test separators

• Well production control modules

• Steam let down stations

• Circulation transfer pumps

• Line heaters

More Highlighted Projects

Click below for more project profiles that highlight our engineering consulting capabilities in a variety of industrial engineering markets.

Is quality supply chain management really that important when constructing energy facilities?

Energy industry upgrade using artificial intelligence?

3 ways to enhance energy industry safety!

Steam-Assisted Gravity Drainage (SAGD) Greenfield Expansion

Largescale Heavy Oil Processing Facility