The energy industry is one of the most challenging and rewarding sectors for engineers. They work on complex projects that involve high-risk activities and cutting-edge technologies. However, these projects also pose significant safety hazards for workers, such as fire, risk of exposure to chemicals, and high-pressure wells. Engineers need to apply engineering and technical solutions to ensure safety throughout the asset lifecycle, from design and construction to operation and maintenance.

Exxon Mobil recently stood down activities across all U.S. shale rigs due to reoccurring safety events. “The safety and health of our workforce is always our top priority. Whenever there is an incident, we double our efforts to reinforce safety,” Exxon said in response to the accidents.

More than 10 years on from the Deepwater Horizon accident, a 2023 report by the U.S. National Academies of Science, Engineering, and Medicine suggests that more still needs to be done to introduce: “An industry-wide emphasis on strengthening safety and guidance for all operators and contractors”.

In this article, we will explore three ways to apply technical solutions to enhance safety in the energy industry:

- Initial Engineering Design

- Construction Management Practices

- Operation Management

Initial Engineering Design

One of the first steps to create a safe environment in the energy industry is to incorporate safety principles and standards into the engineering design of the assets. Engineering design focusses on defining the specifications, functions, features, and performance of a system. Specialized engineering design is critical for safety, as it determines how the system or component will behave under normal and abnormal conditions.

To improve engineering design for safety, engineers need to follow a systematic approach that includes:

- Hazard identification: identifying the potential sources of harm or damage that could affect the system or component.

- Risk assessment: evaluating the likelihood and severity of the harm or damage that could result from the hazards.

- Risk reduction: selecting and implementing appropriate measures to eliminate or minimize the risks.

Some of the measures that engineers can use to reduce risks in engineering design are:

- Inherent safety: designing the system or component to avoid or minimize hazards by using less hazardous materials, processes, or energy sources.

- Passive safety: designing the system or component to withstand or mitigate hazards without requiring human intervention or external power sources.

- Active safety: designing the system or component to detect and respond to hazards by using sensors, controllers, actuators, or alarms.

- Functional safety: designing the system or component to achieve a specific safety function in response to a hazardous event by using software, hardware, or both.

As the state-of-the-art energy exploration advances, new technologies and practices are being developed to further improve the safety performance of facilities. From enhanced Blow-Out Preventer systems (BOPs) to the design of un-manned oil rigs, the industry is moving at pace to reduce accidents and improve safety.

Construction Management Practices

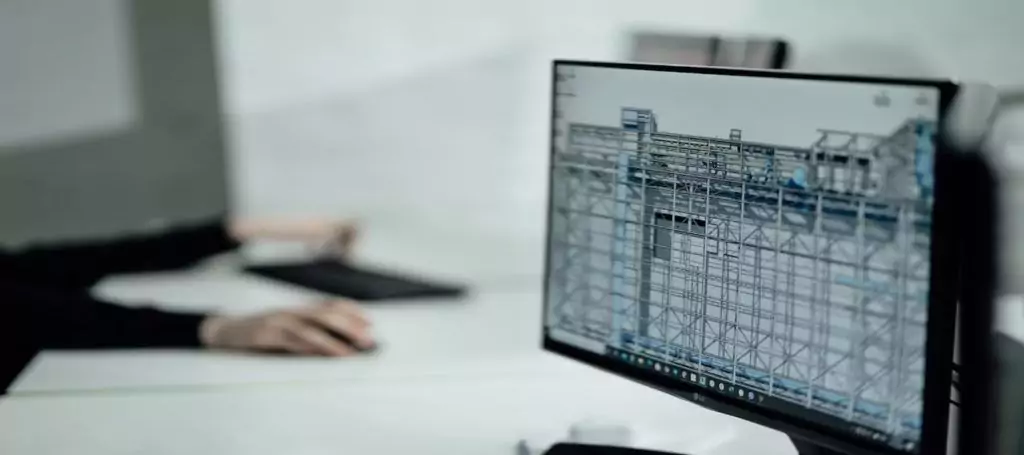

The second step to achieve safety in the energy industry is to ensure proper construction and project management of the assets. Construction management is the process of planning, coordinating, executing, monitoring, and controlling the physical activities involved in building a system or component. Construction management is essential for safety, as it affects the quality, reliability, and durability of the system or component.

The adoption of modern construction and project management practices has been shown to greatly improve the quality and increase the safety records of oil and gas facilities. Advanced Work Packaging (AWP) is one such technique. AWP is a methodology to improve the execution of capital projects in complex industries and challenging environments. AWP is based on the principle of aligning engineering, procurement, construction, and commissioning activities around well-defined work packages that are planned and delivered in a logical sequence.

AWP can improve safety in oil and gas projects by:

- Reducing rework, delays and conflicts that can cause accidents, injuries or fatalities

- Enhancing communication and collaboration among project stakeholders, including contractors, subcontractors, suppliers and regulators

- Increasing predictability and visibility of project progress and performance, allowing for early detection and mitigation of risks

- Improving quality and compliance of work packages, ensuring that they meet the design specifications, standards and regulations

- Optimizing the use of resources, such as labor, equipment and materials, reducing waste and environmental impact

Operation and Maintenance

The third step to achieve safety in the oil and gas industry is to ensure effective operation and maintenance of the assets. Operation and maintenance are the process of running, servicing, repairing, and upgrading a system or component. Operation and maintenance are crucial for safety, as it affects the performance, availability, and efficiency of the system or component.

To improve operation and maintenance for safety, engineers are leveraging digital technologies, such as cloud computingCloud computing is a method of delivering IT services where resources and data are retrieved from the Internet using web-based applications ..., data analytics, artificial intelligence (AI), and the Industrial Internet of Things (IIoT), to monitor performance, detect anomalies, diagnose problems, and optimize processes. For example:

- Sensors can collect real-time data on temperature, pressure, flow rate, vibration, corrosion, and send it to a cloud-based platform for analysis.

- Algorithms can identify patterns, trends, deviations, and risks, and provide recommendations or alerts for corrective actions.

- Controllers can adjust parameters or activate actuators to maintain optimal conditions or prevent failures.

- Drones can inspect hard-to-reach areas or hazardous environments to collect visual or thermal data.

- Virtual or augmented realityaugmented reality (AR) is the superimposition of digital data, usually an image, onto real-world objects to enhance the user’s understandi... can provide immersive training or guidance for operators or technicians.

Conclusion

The energy industry offers many engineering opportunities for those who are interested in working on challenging projects that require technical expertise, creativity, and problem-solving skills. However, these projects also pose significant safety hazards for workers, such as fires, explosions, toxic chemicals, and high-pressure wells.

Engineers need to apply engineering and technical solutions to ensure safety throughout the asset lifecycle, from design and construction to operation and maintenance. By doing so, engineers can not only protect the lives of workers, but also improve the operational efficiency, reduce the costs, enhance the reputation, and attract the talent of the oil and gas companies.

Vista Projects is an integrated engineering services firm able to assist with your industrial projects. With offices in Calgary, Alberta, Houston, Texas, and Muscat, Oman, we help clients with customized system integration and engineering consulting across all core disciplines. Contact one of our experts today at: businessdevelopment@vistaprojects.com