Toe-To-Heel Air Injection (THAI)

Overview

Client

A mid-sized oil and gas owner-operator.

Project facility

Commerical-scale in-situ combustion facility.

Situation

This pilot plant was a commercial-scale in-situ combustion facility that incorporated Petrobank’s proprietary toe-to-heel air injection technology.

The THAI process was believed to offer a number of potentially significant resource, economic, and environmental benefits when compared to other in-situ oil sands recovery processes, including:

- increased resource recovery

- production of a partially

- upgraded bitumen product

- reduced natural gas use

- production of a surplus of

- high-quality industrial water

- reduced diluent requirements

- reduced greenhouse gas emissions

- lower capital and operating costs

Solution

Handling large volumes of sand entrained in the emulsion proved to be an interesting engineering challenge when designing the connecting pipelines.

Vista’s integrated engineering team provided detailed engineering design for this facility.

The project’s focus was the engineering design of four pads with five well pairs each, complete with wellhead separators.

Two of the pads acted as accumulation points for oil emulsion and also accommodated other equipment, including air compressors, tanks, glycol heaters, and steam generation equipment.

Outcomes

Vista’s experienced multi-discipline engineering team ensured that a delicate balance was reached to keep liquid velocities low enough to avoid pipeline erosion, yet high enough to avoid a sand deposition.

Toe-to-Heel Air Injection Equipment & Technology

Aboveground pipelines connecting the new pads to the central processing facility (CPF) included a 20″ sour gas line, a 6″ sour oil emulsion line, a 6″ produced water line, a 12″ high-pressure airline, a 6″ boiler feedwater line, a 4″ fuel gas line and a 4″ recovered condensate line. An existing 3″ fuel pipeline located under one of the new pad sites required Vista to reroute the existing line.

This existing pipeline was located under the new pad site, and commercial expansion plans posed a risk of long-term service interruption for the facility. In response, Vista rerouted the existing pipeline away from the new pad site, enabling the facility to maintain production levels while the new steel pipeline was tied in from the connection point to the rack piping.

What is Toe-to-Heel Air Injection?

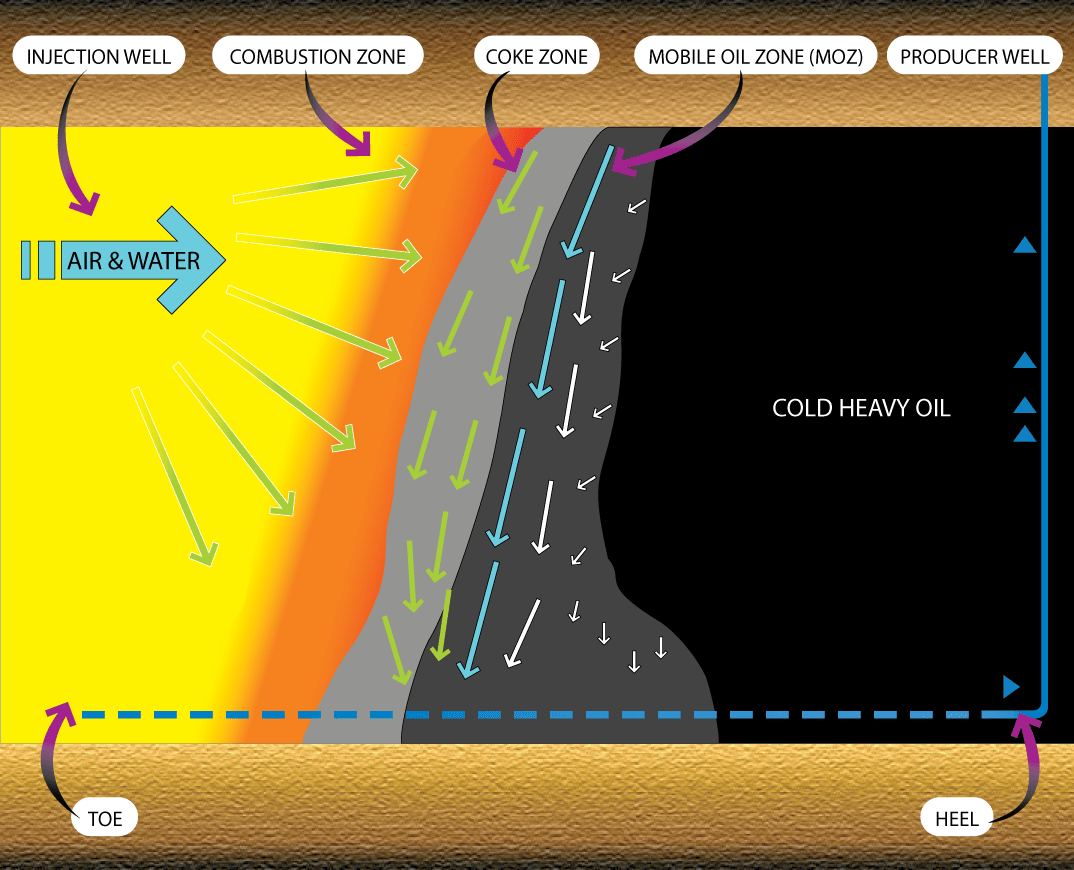

Toe-to-heel air injection (THAI) is an in-situ combustion process used as a petroleum recovery method. It generally combines vertical injection wells and horizontal production wells.

The diagram of the THAI process demonstrates how air is injected to create a fire flood in the combustion zone. As the bitumen, or cold heavy oil is heated, it flows underground from the toe to the heel.

It is pumped back to the surface via the producer well. Once the produced fluids reach the surface, they are processed into crude oil and sold to market.

The detailed engineering project referenced here was for a commercial-scale pilot plant used to extract heavy oil from the reservoir.

A Brief Overview of THAI Technology

THAI technology was developed by Malcolm Greaves in the late 1990s. It was first field-tested in the Athabasca Whitesands in Canada from 2006-2011 and its recovery rates are between 70% and 80%.

For this method, a horizontal production well is drilled, and a vertical well is drilled at its toe. Steam is injected into the vertical well to heat the surrounding area, also known as the combustion zone.

Afterward, the air or oxygen is injected into the combustion zone and a fire is ignited. Injection of air continues to fuel the fire and it moves toward the heel of the horizontal well. As it burns, it heats the oil in place and allows it to drain into the horizontal production well.

The combustion zone is can be maintained at temperatures of over 600C.

This pilot plant was a commercial-scale in-situ combustion facility that incorporated the Petrobank’s proprietary toe-to-heel air injection technology.

The THAI process was believed to offer a number of potentially significant resource, economic and environmental benefits. When compared to other in-situ oil sands recovery processes, including:

- increased resource recovery

- production of a partially

- upgraded bitumen product

- reduced natural gas use

- production of a surplus of

- high-quality industrial water

- reduced diluent requirements

- reduced greenhouse gas emissions

- lower capital and operating costs

Handling large volumes of sand entrained in the emulsion proved to be an interesting engineering challenge when designing the connecting pipelines.

Engineering Applications

The technical knowledge and engineering consulting capabilities demonstrated in this THAI project also apply in other industrial markets.