According to research, the oil and gas sector is the second-largest single generator of greenhouse gas (GHG) emissions. The industry releases well over 13 million metric tons of methane annually, which has a 28–36 times larger potential to cause warming than CO2.

Pollution from fossil fuels can cause cardiovascular, respiratory, and other diseases, accounting for more than 13% of all deaths among Americans aged 14 and older. In addition, the processing of fossil fuels can release dangerous chemicals into the soil and underground water sources.

Energy corporations are also being criticized for wasting and depleting valuable resources. The corporations employ fracking techniques that require massive quantities of water, mainly when drought is rising worldwide, and oil extraction is destroying valuable land.

The pandemic exposed many cracks in the industry that culminated in years of inaction, postponing the inevitable for profits and suppressing scientific research into the harmful effects of the industry’s operations.

In North America, steps have been taken over the years to address the key questions, with vast improvement in some areas. These green technologies are the foundation of sustainability as it stands.

In this article, we talk about what they are and how they’re helping.

Recycled Water

Because of their technical experience, building skills, and access to investment capital, energy corporations are especially suited to address the complex concerns of water sustainability in many parts of the world.

Water hazards may disrupt production, raise operational costs, and harm perceptions and relations with regulatory bodies and local communities. In North America, one of the methods used is “cogeneration.” Extra energy from routine processes, such as steam or heat, can generate more electricity.

Because the water needs for cogeneration are frequently smaller than those for coal-burning boilers or steam-condensing turbines, this boosts efficiency and can contribute to conservation measures.

Given the more sophisticated infrastructure, the electricity generated, consumed by the refinery (cutting the electrical demand that could be imposed on the power utility), or supplied to the power company (expanding the current electricity supply) consumes less water.

In looking at water conservation and sustainability, two researchers from Duke University found that the amount of water being used to produce energy from fossil fuels is much larger than previously thought, and in calculating the footprint, the industry has to factor in water contaminated by its activities, not just water used.

Digital Engineering (Digital Twins)

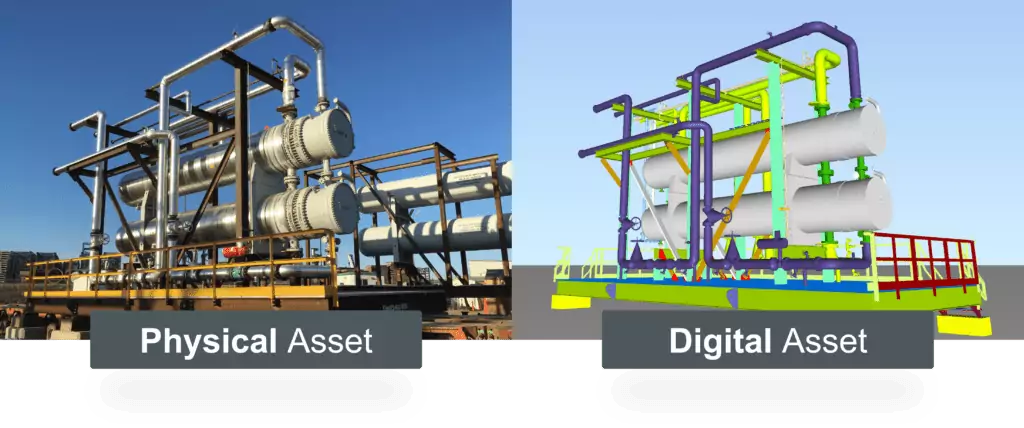

Digital twins are critical for oil and gas firms in getting data used to enhance asset environmental performance and efficiency by including sustainability features while optimizing production, limiting energy consumption, and decreasing emissions.

This provides credible information for fiscal analysis of environmental, social, and governance (ESG) issues, as well as the presentation of a viable strategy for reaching net-zero objectives and deadlines.

Energy firms may interpret all assets, encompassing hydrogen, wind, carbon capture and storage (CCS), and electrification, utilizing digital twins to drive the energy transition with enhanced economics and sustainability in low-margin conditions. Asset values may be adjusted, and scenarios tested, easing the transition to cleaner energy and improving emissions control.

Emissions can be discovered and reported across the supply chain, and the entire environmental impact can be adequately assessed and reduced as the capacity of the digital twinA digital twin is a precise, virtual representation of a physical object system, process, or asset. Digital twins integrate machine learnin... grows.

Sustainable Purchasing/Procurement

Sustainable procurement (also known as “green procurement”) connects corporate social responsibility (CSR) ideals with a company’s procurement processes. It evaluates the environmental, economic, and social effects of the company’s procurement procedures and their influence on quality and prices.

Sustainable buying considers waste disposal and maintenance throughout the life of the oil and gas produced. As a result, it contributes to developing a circular economy that lowers harmful social, economic, and ecological repercussions.

Improved Operational Efficiency

One of the most straightforward approaches to lowering the sector’s pollution is to spend on efficiency improvements that minimize its operational footprint. Digital technology advancements can open new avenues for the industry to improve efficiency.

For instance, enhanced technology might contribute to more precise targeting of profitable reservoirs and reduce the number of “dry holes,” lowering the aggregate energy consumed for oil and gas production activities.

Another strong potential to boost the effectiveness of oil and gas production is to minimize flaring and methane production, notably because methane is the industry’s biggest direct contribution to greenhouse gases. Because methane is a monetizable commodity, the return on emission reduction makes mitigation more commercially viable.

The Development of New Technologies

Petroteq’s Clean Oil Recovery Technology represents one of the best examples of a North American company greening the oil and gas industry. CORT, led by R.G. Bailey, a chemical engineer who formerly served as President of Exxon in the Arabian Gulf region for five years, makes it feasible to recover oil from oil sands without using water.

That means no effluent and toxic tail lagoons, which have posed significant environmental challenges for the oil sands industry. CORT is a closed-loop system, reclaiming and reusing over 95% of the solvents used in extraction. The remaining 5% is retained in the oil obtained.

The sand is decontaminated and becomes ecologically pure soil after the ore is cleaned of oil using CORT technology. The land is spared during the process instead of holding toxic ponds.

Is The Oil and Gas Industry Doing Enough?

The energy sector – among other industries – in North America needs to do more in the future to combat climate change. More public-driven and government-backed policies need to come into play more aggressively to combat this issue.

Planning a Green Technology project?

Vista Projects is an engineering and system integration consultancy that helps companies build green technology projects and more. With offices in Alberta, Calgary; Houston, Texas; and Muscat, Oman, our aim is to help clients achieve their project goals. Get in touch with us today!