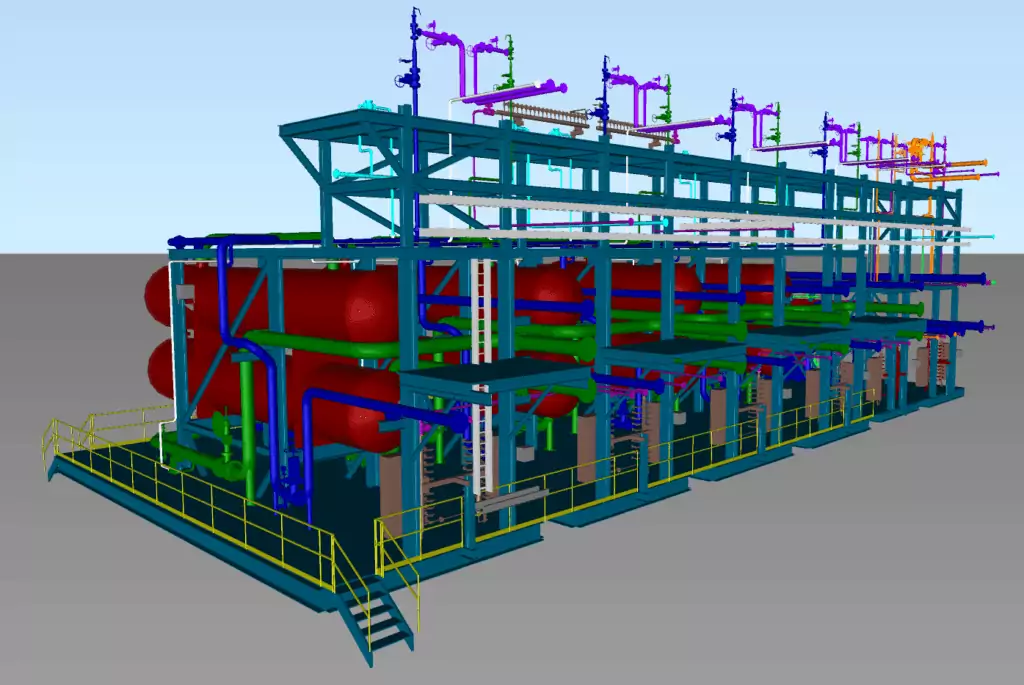

Vista has engineered some of the most successful large-scale processing facilities in the Canadian energy sector. A key success factor has been our relentless optimization of modularized designs in facility engineering.

Below is a video presentation by Shane Balicki, one of Vista’s modularization experts.

Proper Planning

Modularization optimization requires proper planning prior to beginning the engineering design. Before work on the plot plan begins, Vista researches both the location of the facility and the module fabrication yard. This forms part of a detailed transportation study that helps minimize risk later in the project.

Plot Plan Design and Development

With the transportation requirements understood, Vista begins to develop the plot plan and considers the following deliverables, before building the 3D model:

- Transposition Lines

- Preliminary Loop Locations

- Area Key Plans

- Module Key Plans

- Accelerated Modules

Model development doesn’t begin until the Area Key Plans and the Module Key Plans are complete. Each discipline is given its hierarchy and modelling is based on the area number and module number. This is a highly collaborative, multi-disciplinary process.

Optimization Opportunities

Taking advantage of the following opportunities can help reduce cost and increase project efficiencies.

- Avoid designing and shipping empty modules

- Modularize pipe rack loops to minimize field hours

- Modularize buildings to reduce cost

- Lower pipe racks to reduce quantities

- Incorporate work platforms in the module design

Modularization Brochure

Say No to Empty Modules

With proper planning, there is no need to ship air to the site.

When designing modules, Vista always looks to:

- Reduce quantity

- Reduce cost

- Lower height

- Add a compressed design to the plant

Fit-for-Purpose Design

An over-modularized design can increase project costs. The key to finding a project’s modularization sweet spot is to modularize where it makes sense and focus on optimization over maximization.

Vista’s approach is to develop fit-for-purpose engineering designs and focus on cost-effective solutions.

Project Cost vs % Modularization

Module Reporting

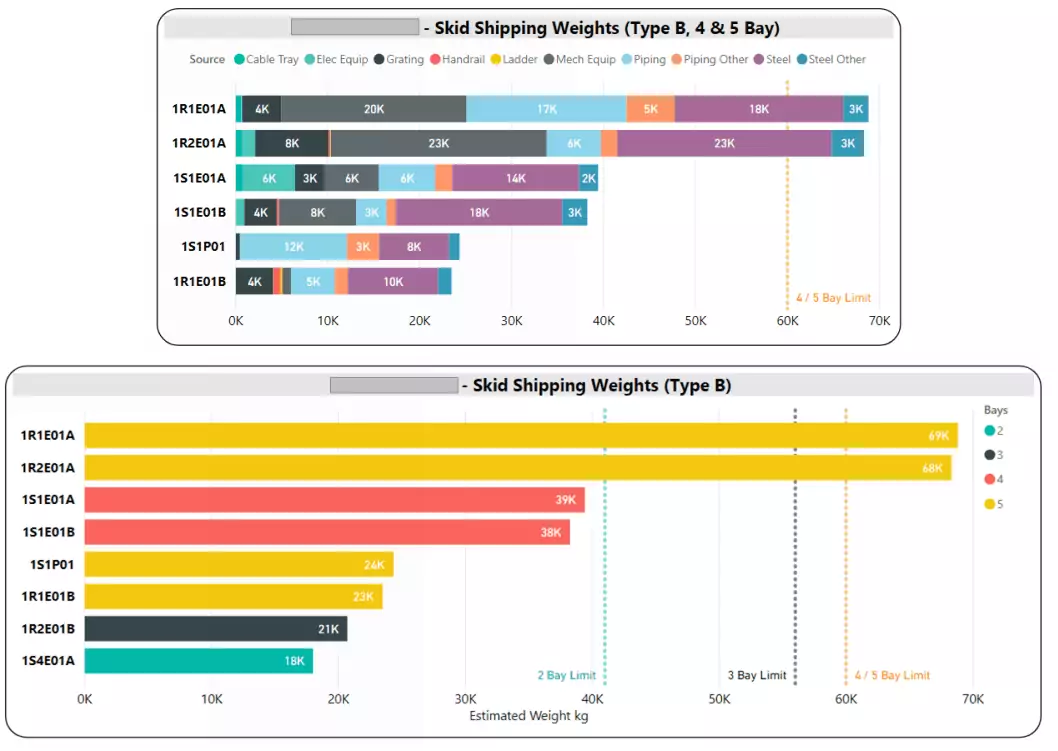

As with all elements of project execution, Vista takes a data-centric approach to modularization. This streamlines module reporting and gives our clients access to a live technical directory, in which they can view key metrics in a user-friendly dashboard and export module lists, isometric skid drawings, MTOs module weights, and more.

The technical directory uses Vista’s intelligent engineering data to cross-reference all elements and gives all stakeholders near-live access to everything they need to know about the project.