When it comes to keeping control panels functioning at their best, thermal management takes center stage. It’s not just about preventing gadgets from overheating; it’s about ensuring they work efficiently and last longer. Reliable electrical engineers play a vital role in designing and implementing effective thermal management solutions that maintain system performance and prolong equipment lifespan. This article dives deep into the world of thermal management within control panels, exploring why it’s so crucial and how it impacts the performance and longevity of these essential devices.

From understanding the negative effects of heat on electronic components to implementing strategies to keep things cool, we cover it all. Whether you’re dealing with manufacturing processes, data centers, or telecommunications infrastructure, mastering the art of thermal management is key to reliability and efficiency. Join us as we unpack the importance of keeping control panels at their optimal temperature, the strategies to achieve it, and the latest trends in thermal management technologies.

Why is Thermal Management Crucial for Control Panels?

Thermal management plays a pivotal role in the operation and longevity of control panels, serving as the backbone for maintaining optimal performance and reliability in various industrial and technological applications. At its core, the essence of thermal management within control panels is to dissipate heat effectively, a crucial aspect due to the detrimental effects excessive heat can have on electronic components. These effects range from reduced operational efficiency to the potential for complete system failure, underscoring the importance of regulating temperature within these systems.

Electrical engineering services are essential in developing and implementing these thermal management solutions, ensuring systems are designed with the right strategies and technologies in place. Thermal management is indispensable in the realm of control panels, serving not only to safeguard the electronic components from the adverse effects of heat but also to ensure the efficiency, reliability, and longevity of these critical systems.

Through a combination of appropriate design considerations and the use of advanced cooling technologies, effective thermal management addresses the inherent challenge of heat dissipation, thereby supporting the seamless operation of control panels across a myriad of applications.

Prevents Overheating and Potential System Failure

Effective thermal management within control panels is crucial for preventing overheating, a common cause of potential system failure. By dissipating excess heat generated during operation, thermal management strategies ensure that the temperature within the control panel remains within safe limits. This not only protects sensitive electronic components from the adverse effects of high temperatures but also safeguards the entire system against the risk of failure.

Preventing overheating is fundamental to maintaining the integrity and functionality of control panels, making it a critical aspect of system design and maintenance.

Ensures Operational Efficiency and Performance

By keeping control panels within their optimal temperature range, thermal management directly contributes to operational efficiency and performance. Electronic components, when operated within their designated thermal limits, perform more reliably and efficiently. This is particularly important in applications where control panels are crucial for continuous, uninterrupted operation, such as in manufacturing processes or data centres.

Effective thermal management ensures that these systems can handle the demands placed upon them without succumbing to heat-induced slowdowns or errors, thereby optimising performance and productivity.

Extends Component Lifespan, Reducing Maintenance Costs

One of the most significant benefits of effective thermal management is the extension of component lifespan within control panels. High temperatures can accelerate wear and tear on electronic components, leading to a shorter operational lifespan and increased susceptibility to failure. By mitigating these temperature extremes, thermal management strategies prolong the life of these components, ultimately reducing the frequency and cost of maintenance and replacements.

This not only results in cost savings but also contributes to environmental sustainability by reducing electronic waste.

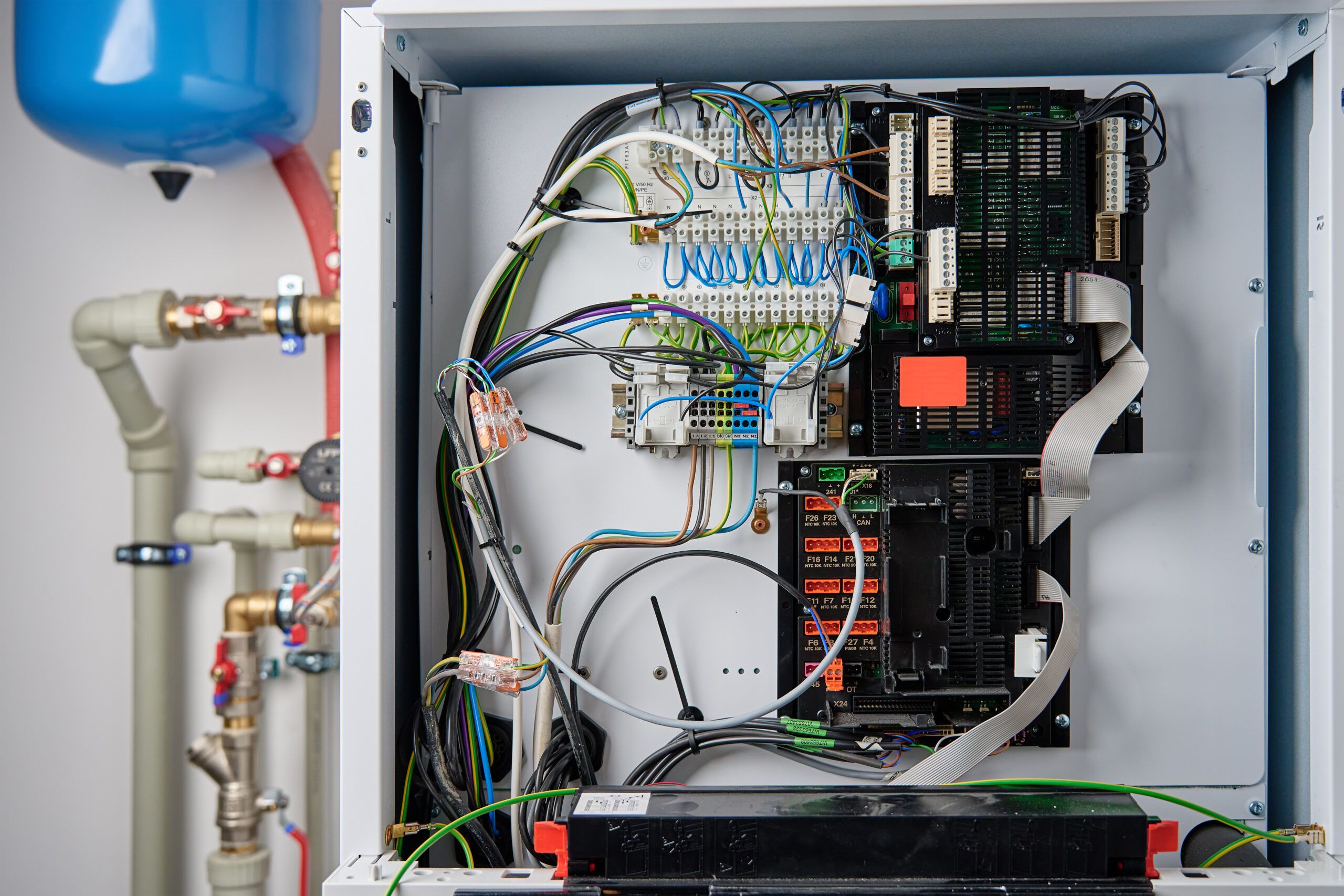

Identifying Heat Sources in Control Panels

Identifying heat sources within control panels is crucial for effective thermal management. Understanding these heat sources is essential for selecting the appropriate cooling strategies to maintain optimal operational temperatures and prevent system failures.

Heat Generated by Electrical Components Under Load

Electrical components under load, such as semiconductors, resistors, and circuit boards, are primary sources of heat in control panels. These components release heat as they consume power, a process inherent to their operation. Managing this heat is vital to prevent overheating and ensure the longevity and reliability of the system.

Ambient Temperature Increases Due to External Conditions

Ambient temperature increases, influenced by external conditions, can significantly affect the internal temperature of control panels. Factors such as the location of the panel, exposure to sunlight, or the temperature of the surrounding environment can contribute to the overall heat load. Understanding the impact of these conditions is crucial for designing an effective thermal management strategy.

Methods for Managing Heat in Control Panels

Managing heat in control panels involves a combination of passive and active cooling techniques. Passive cooling, such as utilising natural convection and using heat sinks, relies on the natural flow of air and heat-dissipating materials to reduce temperatures. Active cooling solutions, including fans, blowers, air conditioners, and heat exchangers, forcibly remove heat from the panel, offering precise temperature control.

Selecting the right method depends on assessing the thermal load, environmental conditions, and space availability, ensuring the control panel operates efficiently and reliably.

Passive Cooling Techniques

Passive cooling techniques utilise the environment to regulate the temperature within control panels without relying on external power sources. This approach is energy-efficient and cost-effective.

Utilising Natural Convection to Dissipate Heat

Natural convection plays a crucial role in passive cooling by allowing hot air to rise and escape, making room for cooler air to fill the space. This process effectively reduces the temperature inside the control panel.

Implementing Heat Sinks to Absorb and Disperse Heat

Heat sinks are designed to absorb excess heat from critical components and dissipate it into the surrounding air. They are a key element in passive cooling, enhancing the natural dissipation of heat.

Active Cooling Solutions

Active cooling solutions involve mechanical systems to forcibly remove heat, providing more control over the internal temperature of control panels.

Fans and Blowers for Forced Air Circulation

Fans and blowers are used to create forced air circulation within the control panel, significantly improving the efficiency of heat removal compared to natural convection alone.

Air Conditioners for Precise Temperature Control

Air conditioners in control panels offer precise temperature control, making them ideal for situations where maintaining a specific temperature range is critical.

Heat Exchangers for Transferring Heat Outside the Panel

Heat exchangers transfer heat from inside the control panel to the outside environment, effectively managing the internal temperature without significantly altering the ambient conditions.

Selecting the Appropriate Thermal Management Solution

Selecting the right thermal management solution for control panels requires a careful analysis of the thermal load, environmental conditions, and space availability. Understanding the specific heat generation characteristics of the electrical components and the ambient conditions they operate in is critical. This ensures the chosen cooling method, whether passive or active, effectively maintains optimal temperatures, enhances system reliability, and ensures energy efficiency.

Balancing these factors with budget constraints is key to achieving a sustainable and efficient thermal management strategy.

Assessing the Thermal Load for Accurate Needs Analysis

Assessing the thermal load is essential for determining the specific cooling requirements of a control panel. This involves calculating the amount of heat generated by the electrical components under operational conditions to select a thermal management solution that can efficiently handle the heat output.

Considering Environmental Conditions Affecting Panel Location

Considering environmental conditions is crucial in selecting an appropriate thermal management solution. Factors such as ambient temperature, humidity, and exposure to sunlight can significantly impact the effectiveness of cooling strategies, necessitating adjustments to ensure optimal performance.

Evaluating Space Availability and Budget Constraints

Evaluating space availability and budget constraints plays a vital role in the selection process of thermal management solutions. The physical dimensions of the control panel and the allocated budget can limit the options available, making it important to find a balance between performance, size, and cost.

Challenges in Effective Thermal Management

Effective thermal management in control panels faces several challenges, including balancing cooling efficiency with energy consumption, adapting to fluctuating environmental temperatures, and ensuring the reliability and durability of cooling systems. These challenges require a comprehensive approach that takes into account the dynamic nature of thermal loads and environmental conditions. Innovations and advancements in cooling technologies aim to address these issues, ensuring that control panels operate within their optimal temperature range while minimising energy usage and maximising system longevity.

Balancing Cooling Efficiency with Energy Consumption

Balancing cooling efficiency with energy consumption is a key challenge in thermal management. Achieving optimal cooling without significantly increasing energy consumption requires innovative solutions that maximise efficiency and minimise waste.

Adapting to Fluctuating Environmental Temperatures

Adapting to fluctuating environmental temperatures demands a responsive thermal management system. Control panels must maintain stable internal temperatures despite external temperature variations, necessitating adaptable cooling strategies.

Ensuring Cooling Systems’ Reliability and Durability

Ensuring the reliability and durability of cooling systems is crucial for uninterrupted operation. Thermal management solutions must withstand the rigors of their environment, providing consistent performance over time without frequent maintenance or replacement.

Trends in Thermal Management Technologies

The landscape of thermal management technologies is evolving rapidly, with innovations aimed at enhancing efficiency, reliability, and sustainability. Key trends include the integration of smart cooling systems with the Internet of Things (Iot) for real-time monitoring and control, the adoption of phase change materials (PCMS) for superior heat absorption and dissipation, and the development of compact, efficient cooling solutions suitable for space-constrained environments. Collaborating with a professional engineering consultant can help ensure these technologies are implemented effectively, tailored to specific system requirements, and aligned with both performance and environmental goals. These advancements reflect the growing need for thermal management solutions that not only meet the increasing thermal loads of modern electronic components but also align with energy efficiency and environmental sustainability goals.

Integration of Smart Cooling Systems with IoT

The integration of smart cooling systems with IoT enables advanced monitoring and control over thermal management processes. This technology allows for real-time adjustments, optimising cooling efficiency and reducing energy consumption.

Adoption of Phase Change Materials for Enhanced Heat Absorption

Adoption of phase change materials (PCMs) is gaining traction for their ability to absorb and release heat during phase transitions. This property significantly enhances heat management in control panels, providing a passive cooling effect that reduces the need for active cooling components.

Development of Compact, Efficient Cooling Solutions for Space-Limited Panels

The development of compact, efficient cooling solutions addresses the challenges posed by space-limited environments. These innovations offer effective thermal management in smaller footprints, crucial for modern electronic devices and control panels where space is at a premium.

Keeping Control Panels Cool for Peak Performance

Thermal management is a critical element in ensuring the reliability and longevity of control panels. Effective heat dissipation prevents overheating, optimises operational efficiency, and extends the lifespan of components. Whether through passive techniques like heat sinks or active solutions such as fans and air conditioners, maintaining the right temperature is key to avoiding system failure and enhancing overall performance. The challenge lies in selecting the appropriate solution based on the thermal load, environmental conditions, and space constraints, while balancing energy efficiency and cost.

At Vista Projects, we specialise in designing and integrating efficient thermal management solutions that ensure optimal performance for your control panels. Our team of skilled electrical engineers helps identify the best strategies tailored to your specific needs, maximising reliability and energy efficiency.

Ready to enhance your control panel’s thermal management? Contact Vista Projects today to learn how we can optimise your system for performance and longevity.