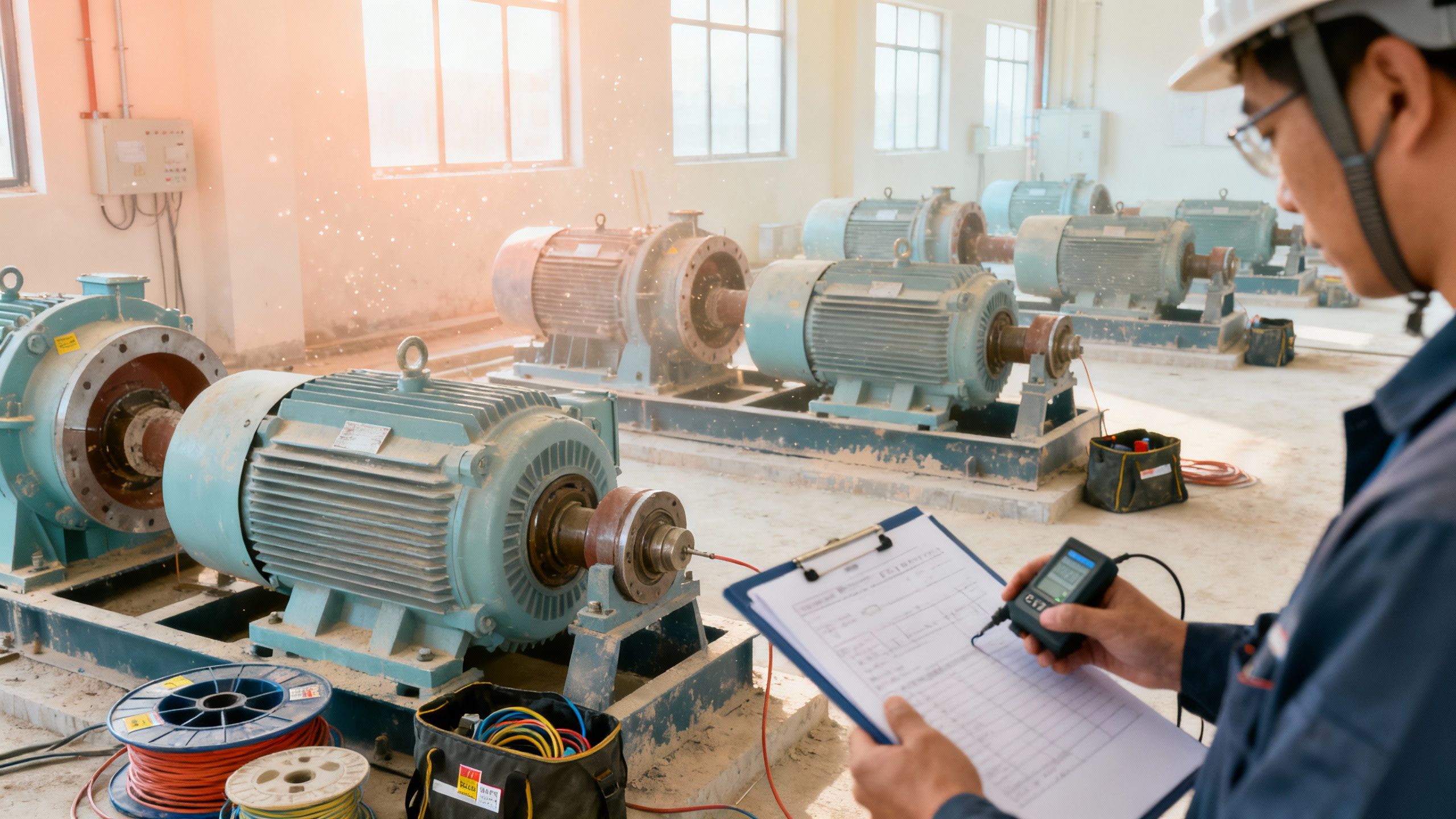

You’ve seen it happen. A brand-new 500 HP motor arrives on site after six months in a shipping container, gets bolted down, wired up, and someone hits the start button without proper testing. Thirty seconds later, you’ve got a seized bearing, a tripped breaker, and a project manager asking why the startup just slipped by three weeks. That motor absorbed moisture during ocean transit, and nobody bothered to test the motor before startup with a 60-second megger reading.

Motor failures during commissioning are almost always preventable with proper motor testing in industrial facilities. The complete sequence takes 4-10 hours per motor, depending on size. Still, it prevents failures that routinely create six-figure project impacts when you factor in downtime, expedited shipping, contractor standby costs, and schedule liquidated damages.

Motor-driven systems typically consume 45-65% or more of electrical energy in industrial facilities. When they fail during startup, the cascade hits your entire process train. A cooling water pump motor failure caused the force to shut down within minutes. An air compressor motor trip starves instrument air, causing control valves to fail-safe. A lube oil pump motor failure on a large compressor train gives you very little time before bearing damage begins.

This guide covers motor testing procedures from pre-energization inspection through solo run acceptance: insulation resistance testing, winding verification, bump tests, rotation checks, and run-in procedures for pumps, compressors, and fan applications.

When that motor fails during the warranty period, and you file a claim, the manufacturer’s first question is: “Show me your pre-startup test records.” No records? Warranty coverage becomes difficult or impossible to obtain. Your commissioning package should include complete motor test documentation, which operations use as baselines for predictive maintenance trending.

For commissioning in Canada, motor testing procedures must align with CSA standards and provincial electrical codes, in addition to manufacturer requirements.

Disclaimer: Motor specifications, testing standards, and regulatory requirements change frequently. All costs, specifications, and acceptance criteria mentioned are approximate. Verify all information with current equipment manufacturer documentation, applicable codes, and local suppliers before making commissioning decisions. Motor testing procedures should follow CSA and IEC standards applicable in Canada.

For Canadian installations, motor testing procedures should comply with CSA standards (including CSA C392 for insulation testing) and applicable IEC standards. Provincial electrical codes may impose additional requirements for motor commissioning and acceptance testing.

Essential Test Equipment for Motor Commissioning

Equipment prices below were approximate as of early 2025. Verify current pricing with your suppliers.

Insulation Resistance Testers

Match your megohmmeter to the motor voltage class. For motors under 1000V, a 500V or 1000V megger handles the job at roughly $1,000-3,000, depending on features. Medium-voltage motors in the 2300V-6900V range need 2500V or 5000V capability, with quality units running several thousand dollars. Above 6900V, you need 10,000V equipment.

Common mistake: testing a 4160V motor with a 500V megger. The insulation might hold 500V perfectly while being compromised at operating voltage.

Safety Warning: High-voltage insulation testing presents serious electrical hazards. Only qualified personnel should perform these tests. Ensure proper lockout/tagout procedures are in place, verify the motor is isolated from all power sources, and use appropriate personal protective equipment (PPE) rated for the test voltages involved. Large motors can store significant energy during testing—always discharge windings properly after testing and maintain grounding connections for at least four times the test duration. Follow your facility’s electrical safety procedures and applicable standards, including CSA Z462 for electrical safety in the workplace.”

Low-Resistance Ohmmeters

Standard multimeters can’t reliably detect the milliohm differences between phases that indicate problems. You need a micro-ohmmeter using four-wire Kelvin measurement, where two wires carry current and two separate wires measure voltage drop. This eliminates lead resistance errors. Quality units typically cost several thousand dollars.

Vibration and Rotation Tools

Portable vibration meters are non-negotiable for solo run testing. Entry-level units run $1,500-$2,500. Measure in three axes because unbalance, misalignment, and bearing defects each show up differently depending on direction.

Phase rotation meters in the $100-$300 range verify rotation direction without energizing. This modest investment prevents costly damage from reverse rotation, particularly on screw compressors, where reverse operation destroys rotor meshes.

Pre-Energization Inspection Sequence

Visual and Mechanical Inspections

Budget 30-60 minutes per motor. Electrical testing won’t catch a cracked frame or a shaft full of rust.

Open every access cover. Check the shaft for scoring and spin it by hand. You want smooth rotation with slight bearing drag, not grinding or catching. Motors that sat in shipping containers for months arrive with surprises, including condensation puddles and debris in terminal boxes.

Coupling alignment: Misalignment is a leading cause of premature bearing failure and significantly increases bearing loads. Tolerances vary by coupling type, speed, and manufacturer.

Soft-foot check: With bolts snugged, place a dial indicator near each foot and loosen the bolts one at a time. Significant movement indicates soft foot requiring stainless steel shimming. Skipping this check is one of the most common commissioning mistakes.

Lubrication verification: For oil-lubricated bearings, verify oil level and quality. For grease-lubricated bearings, confirm the proper grease type and quantity per the manufacturer’s data. Motors with forced-lube systems require separate lube oil pump testing before startup.

Electrical Connection Verification

Open every junction box. Verify proper lug installation and torque connections per manufacturer specifications. Confirm electrical clearances meet code requirements for your voltage class.

For VFD-fed motors, pay close attention to the common-mode ground path. Poor grounding causes bearing currents that damage races and balls.

Hazardous area motors: For Class I Division 1/2 or Zone 1/2 installations, verify explosion-proof or increased safety enclosure integrity. Check that all bolts are preset, that conduit seals are properly installed, and that certifications match the area classification requirements.

Control System Integration Checks

Ensure instrument calibration is complete for all sensors providing motor protection inputs, including temperature and vibration transmitters. Before motor testing begins, verify control system readiness:

- Loop checks complete for motor status and control signals

- Interlock logic tested (process permissives, safety interlocks)

- Protection relay settings verified and documented

- Emergency stop circuits tested from all local stations

- DCS/PLC motor control logic validated in simulation

Your SCADA system should be configured to display motor status, alarms, and protection data before commissioning begins.

Nameplate Verification

Compare the installed motor nameplate against your specifications. Verify voltage matches supply configuration. Confirm insulation class suits the application, keeping in mind that VFDs typically require Class F or H. Check that the speed matches the driven equipment requirements.

Insulation Resistance Testing

Selecting Test Voltage

IEEE 43 and IEC 60034-27 provide guidance on selecting test voltage based on the motor’s voltage rating. For Canadian installations, CSA C392 addresses insulation testing procedures. Generally, the test voltage should be appropriate to the motor’s voltage class.

VFD-fed motors see peak voltages well above their nominal rating due to PWM switching reflections, especially with longer cable runs. If the motor will see significant transient peaks in service, a lower-voltage insulation test may not reveal all potential problems.

Step-by-Step Megger Testing Procedure

How long does insulation resistance testing take?

Plan 15-30 minutes per motor, including safety prep. For Polarization Index testing with its 10-minute duration, budget 45-60 minutes total.

- Verify isolation and apply LOTO.

- Discharge windings with a grounding stick before connecting your megger

- Test phase-to-ground on each phase, holding for at least 60 seconds

- Test phase-to-phase combinations

- Record temperature for correction calculations

- Discharge after testing, maintaining a connection for at least four times your test duration

Large motors store significant energy during high-voltage testing. Treat discharge seriously.

Interpreting Results

IEEE 43 and IEC 60034-27 provide formulas for minimum acceptable insulation resistance. For Canadian projects, CSA standards should also be consulted. Those calculated minimums are survival thresholds, not quality indicators. New motors typically read hundreds or thousands of megohms.

What does the Polarization Index tell you?

PI is the ratio of 10-minute to 1-minute resistance. Clean, dry insulation continues to climb as it polarizes. PI above four generally indicates excellent condition. PI between n and 2 and 4 is typically acceptable. Below are two warrants for investigation. Below one usually indicates a problem requiring consultation with applicable standards and manufacturer guidance.

A motor with good absolute resistance readings but a flat PI curve has a problem despite those healthy numbers. The insulation isn’t polarizing properly, often indicating moisture or contamination.

When Readings Fail

Moisture contamination causes most low readings and is usually fixable. Energize space heaters for 24-72 hours, checking resistance daily. You should see steady improvement. No space heaters? Distribute heat sources around the motor, targeting modest temperature elevation above ambient.

When drying doesn’t help after 48 hours, you’re probably looking at contamination needing professional cleaning or physical damage requiring rewind evaluation.

Acceptable insulation resistance values vary based on motor size, voltage class, insulation system, and operating environment. Always consult manufacturer specifications and applicable standards for your specific application.

Winding Resistance Verification

Why does phase balance matter for motor life?

Small resistance differences between phases create current imbalances during operation. Those current differences cause unequal heating that accelerates insulation degradation. A high-resistance connection can create a measurable imbalance that shortens motor life.

Measure at motor terminals using your four-wire ohmmeter. The record temperature since copper resistance increases roughly 0.4% per degree Celsius. Comparing a hot motor to cold factory data without correction gives misleading results.

Phase-to-phase variation limits depend on motor design and applicable standards, including IEEE, IEC 60034, and CSA requirements for Canadian installations. Many specifications call for balance within a few percent of the average. Factory acceptance testing records provide the baseline for comparison. If the factory test showed good balance but your field test doesn’t, check terminations, re-torque connections, clean any oxidation, and retest.

Bump Test and Rotation Verification

Safety Requirements

This is where people get hurt. Before first energization:

- Complete every pre-energization test

- Obtain formal LOTO removal authorization and permit to work

- Conduct a job safety briefing with all personnel in the area

- Install coupling guards or disconnect the coupling as appropriate

- Clear an adequate safety perimeter and verify arc flash boundaries

- Position observer with a clear view of the shaft

- Verify emergency stop functionality

Confirm that emergency procedures for electrical failures are in place and communicated to all personnel in the area.

Equipment-Specific Considerations

What equipment requires uncoupled bump testing?

Screw compressors always require uncoupled bump tests because reverse rotation destroys the rotor mesh. Many reciprocating compressors require uncoupled verification due to valve orientation. Positive displacement pumps with check valves or relief valve arrangements may also require uncoupled verification. Centrifugal pumps can typically be bump-tested coupled, but verify the impeller rotation direction markings.

Executing the Test

You want momentary energization lasting only long enough to see the rotation direction without accelerating to full speed. The person at the starter shouldn’t confirm rotation because they can’t see the shaft from the MCC. Use radios for communication.

Wrong rotation means swapping any two phases at the motor terminals or MCC. After swapping, run a bump test again to verify the correction. Document which phases you swapped and where.

Solo Run Testing for Motor Acceptance

Preparation and Monitoring

Before extended no-load operation, verify auxiliary systems are ready: lubrication primed, cooling functional, space heaters de-energized, protection settings enabled.

What should you monitor during a solo run?

- Current draw: No-load current is typically a fraction of full load current, though exact values vary by motor design. All three phases should read reasonably close to each other.

- Vibration: Measure in three axes at each bearing. Initial readings often run slightly higher as the bearings seat. Readings should stabilize or decrease, never increase.

- Bearing temperature: Should plateau above ambient. If temperatures keep climbing without stabilizing, shut down and investigate.

- Noise: Listen for rubbing, grinding, or abnormal electrical hum.

Duration Guidelines

How long should a solo run test last?

Small motors may need only an hour or two. Medium motors often require several hours. Large and critical service motors may require extended runs of four hours or more per API specifications. The key criterion is temperature stabilization, not just elapsed time.

Document readings at regular intervals, commonly every 15 minutes initially, then less frequently as parameters stabilize. Many specifications require witnessed testing with co-signatures.

Solo run duration and acceptance criteria vary significantly based on motor size, application, and manufacturer requirements. Always follow equipment-specific procedures and project specifications.

Motor-Driven Equipment Coordination

Pump Applications

After a successful motor solo run, coupled pump testing requires additional verification:

- Verify pump rotation matches casing arrow

- Check that the minimum flow protection is functional

- Monitor discharge pressure against the pump curve

- Verify seal flush and cooling systems are operational

- Watch for cavitation indicators (noise, pressure fluctuations)

Compressor Applications

Compressor motor testing involves coordination with:

- Lube oil system pre-startup (often requires extended lube pump operation before main motor start)

- Surge control systems for centrifugal compressors

- Unloader verification for reciprocating compressors

- Seal gas systems where applicable

Fan Applications

Fan motor commissioning includes:

- Damper position verification (often starts with dampers closed to reduce starting load)

- Variable pitch blade position verification

- Vibration sensitivity due to a large rotating mass

- Extended run times may be needed due to thermal mass

VFD and Soft Starter Considerations

VFDs introduce complications that don’t exist with across-the-line starting. Entering motor nameplate data incorrectly causes wrong protection settings and mysterious trips. I’ve seen a drive fault labeled “overload” because someone entered the wrong full-load current value.

Carrier frequency selection affects motor noise and heating. Higher frequencies run quieter but increase cable heating and EMI. Lower frequencies produce an audible whine but may stress the system less.

Cable length matters because PWM voltage reflections can significantly boost peak voltage at motor terminals. Consult the drive manufacturer’s guidance for cable length limits and mitigation requirements, such as output reactors or filters.

Soft-starter testing requires verifying start-time settings, current-limiter functionality, and bypass contactor operation. Coordinate thermal protection between the soft starter and motor protection relay.

Verify protection coordination before commissioning is complete. Test thermal overload, locked rotor protection, ground fault, and phase unbalance functions. Motor protection should coordinate properly with upstream protection.

Troubleshooting Common Test Failures

Quick Diagnostic Reference

Low insulation resistance: Suspect moisture first. If drying procedures don’t improve readings after 48 hours, escalate to professional evaluation for contamination or physical damage.

Unbalanced winding resistance: Connection issues are far more common than winding faults. If re-torquing and cleaning don’t resolve the imbalance, compare the factory test report before condemning the motor.

Excessive vibration during solo run: Check soft foot first using the dial indicator method. If that’s not the issue, investigate bearing lubrication, abnormal sounds, and coupling runout.

High no-load current: Verify supply voltage first. Motors amplify voltage imbalance, so check supply balance before assuming motor problems. Also, verify the correct VFD parameters if applicable.

When to call specialists: Persistent abnormal readings after basic troubleshooting, suspected rotor bar issues, or any safety concerns warrant involving qualified motor specialists rather than proceeding with startup.

Common Commissioning Mistakes to Avoid

- Skipping megger test on “new” motors – Shipping and storage can compromise insulation regardless of motor age

- Bump testing screw compressors while coupled – Reverse rotation destroys rotors instantly

- Ignoring soft foot – Creates ongoing vibration problems that shorten bearing life.

- Not recording baseline data – Loses trending capability and warranty documentation.

- Rushing solo run – Temperature stabilization matters more than clock time

- Wrong VFD parameters – Causes nuisance trips or inadequate protection

- Skipping control system integration checks – Creates startup surprises when interlocks don’t function as expected

- Forgetting to de-energize space heaters can damage windings during operation

Making Your Motor Startup Successful

Motor testing in industrial facilities requires systematic execution, not complexity. Visual inspection, insulation testing, winding resistance measurement, bump testing, and solo run all build on each other.

Build site-specific procedures, adapting these principles to your equipment and standards. Start with your next several motors, document everything, and compare results to manufacturer data. You’ll develop intuition for what normal looks like at your facility.

For complex projects where electrical, mechanical, and control coordination determine success, experienced multi-disciplinary engineering partners like Vista Projects can provide commissioning support across Canada that addresses the cross-discipline challenges single-discipline contractors often miss.

Get motor testing right, and the startup becomes predictable. Operations receives equipment with known baselines. Maintenance has trending data from day one.

That’s worth the investment.

This guide is for informational purposes only and should not be considered professional engineering advice. Costs, specifications, and acceptance criteria vary significantly based on equipment, region, supplier, and market conditions. Regulations and standards change frequently. Always consult current manufacturer documentation, applicable codes and standards, and qualified engineering professionals for your specific application. For Canadian installations, ensure compliance with CSA standards, IEC requirements, and applicable provincial electrical codes.