Electricity is the lifeblood of modern society, powering everything from our homes to our workplaces. However, just like any complex system, the electrical distribution network that keeps the lights on and our gadgets charged can run into issues, notably overload. Overloading in distribution lines is not just an inconvenience; it can be a serious safety hazard.

But how do you know if the lines are overloaded? From dimming lights to the unmistakable smell of burning plastic, this article delves into the common signs that indicate trouble in the network. Understanding these signs is not just for electricians; it’s valuable knowledge for anyone who wants to keep their environment safe and powered up efficiently.

So, let’s illuminate the warning signals of overload in distribution lines and what they mean for you.

What are Common Signs of Overload in Distribution Lines?

Overloaded distribution lines, a critical issue in electrical networks, manifest through several tell-tale signs. These signs are essential indicators for maintenance teams to prevent potential hazards and ensure uninterrupted power supply. Understanding these signs is crucial for timely intervention and maintenance.

- Voltage Fluctuations: One of the primary indicators of an overloaded distribution line is significant voltage fluctuations. Users may notice lights dimming or flickering without any apparent reason, which often points to an overload situation where the line cannot handle the electrical demand.

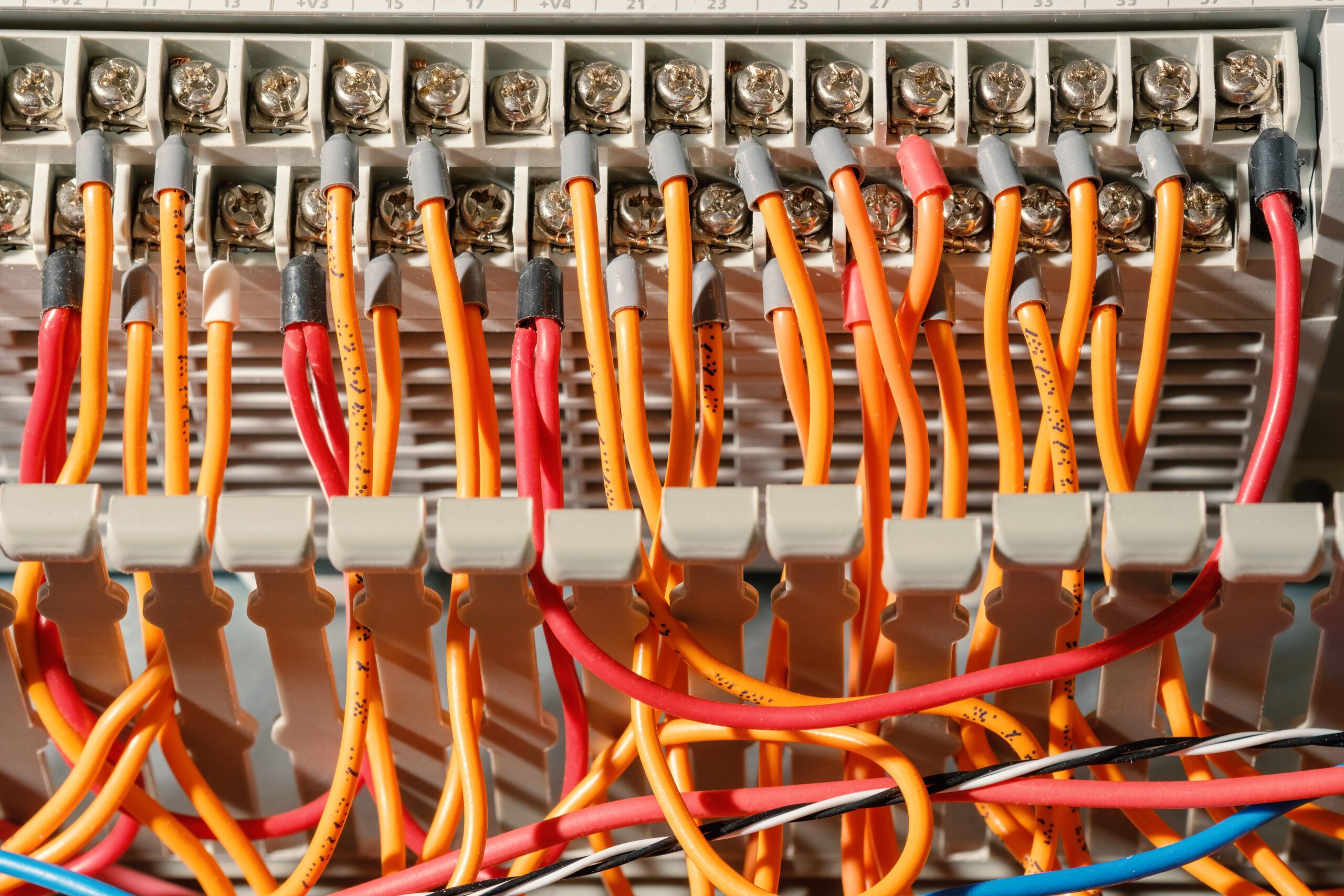

- Overheated Cables: Overloaded lines cause cables to overheat, which can be detected by an unusual warmth emanating from cable conduits or by thermal imaging tools. This overheating can damage the insulation over time, leading to a higher risk of short circuits or electrical fires.

- Tripped Circuit Breakers or Blown Fuses: Frequent tripping of circuit breakers or blown fuses is a common sign of overload. These protective devices are designed to cut off electrical flow when the system is overloaded to prevent damage, serving as an immediate indicator of a problem.

- Humming or Buzzing Sounds: An overloaded distribution line may produce a noticeable humming or buzzing sound. This acoustic signal results from the electrical current straining against the physical limitations of the conductors, indicating that the system is operating beyond its safe capacity.

- Burn Marks or Smell of Burning: Visual and olfactory signs like burn marks around outlets or a persistent smell of burning plastic can indicate severe overloading. These signs often precede dangerous electrical fires and should be addressed immediately.

Identifying and addressing these signs of overload in distribution lines is vital for maintaining the safety and efficiency of electrical distribution networks. Regular monitoring and maintenance can mitigate the risks associated with overloaded lines, ensuring a stable and reliable power supply.

How Does Voltage Fluctuation Indicate Overload?

Voltage fluctuations in a distribution line clearly indicate an overload condition. Such variations not only highlight the immediate issue of overload but also suggest a potential risk to connected equipment and the overall stability of the electrical network. Recognising and addressing voltage fluctuations promptly can prevent further complications, ensuring the safety and reliability of the power distribution system.

Sudden Drops in Voltage

Sudden drops in voltage signal an immediate and significant strain on the distribution network, often pointing to an overload where the demand surpasses the supply capacity. This condition can lead to underperformance of electrical appliances and potential damage over time.

Spikes in Voltage Levels

Conversely, spikes in voltage levels indicate transient overloads, causing a sudden surge in power flow. These spikes can be particularly damaging to sensitive electronic equipment, leading to immediate or cumulative harm.

Why do Circuit Breakers Trip or Fuses Blow in Case of Overload?

Circuit breakers trip and fuses blow as protective measures to prevent wire damage and potential fires in the event of an overload. This automatic response cuts off electrical flow when the current exceeds safe levels, safeguarding the electrical system’s integrity. Such actions are crucial for avoiding the overheating of wires, which could otherwise lead to insulation damage or even catastrophic electrical fires.

By understanding this protective mechanism, individuals can recognise the significance of these occurrences as indicators of an overloaded circuit needing immediate attention.

Preventing Wire Damage

The tripping of circuit breakers and blowing of fuses serve as critical interventions to prevent wire damage. By halting the flow of excessive current, these protective devices help maintain the integrity of the electrical system’s wiring, thus preventing the deterioration that can lead to short circuits and other electrical failures.

Avoiding Potential Fires

Moreover, these safety mechanisms play a pivotal role in avoiding potential fires. Overloaded circuits can cause wires to overheat, increasing the risk of igniting surrounding materials. The prompt action of circuit breakers and fuses in cutting off the power supply mitigates this risk, thereby protecting property and lives from fire hazards.

What Role Does Overheating Play in Signalling Distribution Line Overload?

Overheating is a critical sign of distribution line overload, manifesting in several key components, such as transformers and cables. Overheating of transformers can drastically reduce their efficiency and lifespan, while overheated cables may suffer from insulation damage, elevating the risk of short circuits. This thermal stress signals that the electrical system is operating beyond its capacity, jeopardising both the equipment’s integrity and the safety of the network.

Recognising overheating as an early warning allows for timely interventions, preventing further damage and potential failures within the distribution line.

Overheating of Transformers

Overheating in transformers signals an overload, leading to reduced efficiency and a shortened lifespan for these critical components. This condition compromises their ability to function optimally, affecting the overall reliability of the electrical distribution system.

Reduced Efficiency and Lifespan

The efficiency of an overheated transformer drops significantly as the excessive heat degrades its internal components over time. This not only reduces its operational lifespan but also increases maintenance costs and the likelihood of unexpected failures.

Overheating of Cables

Cables subjected to overload conditions can overheat, posing serious safety risks. This overheating can lead to insulation damage, making the cables more susceptible to short circuits, which can cause outages and pose fire hazards.

Insulation Damage and Risk of Short Circuits

Damaged insulation due to overheating increases the risk of short circuits. Short circuits can lead to sudden power outages and are a significant fire risk, highlighting the importance of addressing overheating issues promptly to maintain system safety and integrity.

How Does the Dimming or Flickering of Lights Relate to Overload?

Dimming or flickering of lights is often a direct consequence of an overloaded electrical system. This phenomenon occurs when the distribution lines are unable to supply enough power to meet demand, leading to inconsistent power supply. Such fluctuations in power can cause lights to dim or flicker, serving as an early warning sign of system stress.

Beyond being a nuisance, these symptoms can indicate a potential for equipment damage if the underlying issue of overload is not addressed. Recognising and responding to these signs promptly can prevent further complications, ensuring the stability and safety of the electrical network.

Indicative of Inconsistent Power Supply

Dimming or flickering lights are indicative of an inconsistent power supply, a common symptom of an overloaded electrical system. This inconsistency can cause fluctuations that are not only noticeable but also signal a deeper issue within the power distribution network.

Potential for Equipment Damage

These fluctuations in power supply can lead to potential equipment damage. Sensitive electronics and appliances may not operate correctly or could be harmed over time due to the unstable power levels, underscoring the importance of addressing the root cause of the overload to protect connected equipment.

Why is the Presence of a Burning Smell a Sign of Overload?

The presence of a burning smell in an electrical system is a critical indicator of overload and potential danger. This odour often originates from overheated components such as wiring or insulation, which can begin to smoulder or melt when subjected to excessive current. Such conditions not only damage the electrical infrastructure but also significantly increase the risk of fire.

The detection of a burning smell signifies that the electrical load exceeds the system’s capacity, causing components to overheat to a point where they may release smoke or emit a burning odour. Addressing this sign promptly is crucial to prevent catastrophic outcomes, ensuring the safety and integrity of the electrical network.

Burning Smell From Electrical Panels

A burning smell emanating from electrical panels is a direct indication of an overload causing components within the panel to overheat. This situation requires immediate attention to prevent further damage or risk of fire.

Melting of Insulation or Components

Overload conditions can lead to the melting of insulation or other components within an electrical system. This melting process releases a distinct burning odour, signalling that the system’s capacity is exceeded and components are at risk of failure.

Burning Smell From Outlets

When outlets emit a burning smell, it often points to overheated wires or faulty connections behind the outlet. This not only poses a fire hazard but also indicates that the electrical demand on the circuit is too high.

Overheated Wires or Faulty Connections

Overheated wires or faulty connections can generate enough heat to cause a burning smell, a clear sign of electrical overload. These conditions compromise the safety and functionality of the electrical system, necessitating prompt investigation and resolution.

What Does Unusual Noise from Electrical Equipment Indicate?

Unusual noise from electrical equipment, such as buzzing sounds from transformers or humming sounds from electrical panels, often indicates underlying issues like loose connections or overloaded circuits. These auditory signals suggest that the equipment is operating under stress or malfunctioning, potentially leading to inefficiencies or safety hazards. Buzzing or humming can specifically point to overloaded breakers or faulty components within the system, highlighting the need for immediate inspection and maintenance.

Recognising and addressing these noises promptly can avert further damage and ensure the reliability and safety of the electrical network.

Buzzing Sounds From Transformers

Buzzing sounds emanating from transformers often signal an overload or an electrical fault within the system, indicating that the transformer is operating beyond its intended capacity.

Loose Connections or Overloaded Circuits

Loose connections or overloaded circuits can manifest as various noises, including buzzing or crackling. These conditions are indicative of an electrical system under strain and require urgent attention to prevent potential failures.

Humming Sounds From Electrical Panels

Humming sounds from electrical panels are typically associated with overloaded breakers or the presence of faulty components. Such noises suggest that the panel is handling more current than it is rated for, or that there is a malfunction needing immediate resolution.

Overloaded Breakers or Faulty Components

Overloaded breakers or faulty components within an electrical system can produce audible signals like humming or buzzing. These sounds serve as a warning that the system is compromised and at risk of overheating or failure, highlighting the need for prompt inspection and maintenance.

When the System Speaks, Listen

From flickering lights and buzzing panels to the unmistakable smell of burning, the signs of overload in distribution lines are clear warnings that shouldn’t be ignored. Recognising these early signals is key to preventing equipment damage, minimising downtime, and safeguarding your electrical infrastructure.

At Vista Projects, we bring precision and foresight to electrical engineering and system integration. Our truth-based approach ensures your power systems are not only built for performance but monitored for resilience.

Don’t wait for a warning sign to become a crisis, partner with Vista Projects to ensure your distribution systems are safe, efficient, and built to last.