An electrical arc flash is as common as it is dangerous.

It’s estimated that 5-10 arc fault incidents occur daily in the United States, resulting in 400 fatalities annually.

An arc flash is like an electrical grenade going off without warning and within feet of workers. The extreme heat, light, and blast pressure can cause:

- Third-degree burns

- Blindness

- Death

When you’re doing maintenance work at an energized facility, arc flash preparedness is of the utmost importance.

And part of being prepared is having an arc flash analysis done at least every five years.

It’s also recommended to conduct a full or partial arc flash study after any changes in relay settings or the addition/deletion of major contributing system loads like big motors or generators.

The study will provide analysis based on arc flash calculations using the latest standards. The findings of a new arc flash analysis could help save lives and improve uptime at your facility.

This article explores how the recent changes to the arc flash standards will impact your calculations.

Arc Flash Safety

The first paper published about the importance of arc flash safety was in 1982 by Ralph H. Lee. The paper explained that an arc flash can be deadly. It also demonstrated how to calculate the worker safety risks related to heat energy exposure.

The electric power industry was somewhat slow to adopt appropriate preventative measures for arc flash. Since the early 2000s, however, companies have rightly paid closer attention to the dangers.

Safety standards established for arc flash hazards are found in:

- National Fire Protection Association (NFPA) 70E Standard for Electrical Safety in the Workplace

- IEEE 1584-2002 – Guide for Performing Arc Flash Hazard Calculations

- This version has been superseded by IEEE 1584-2018

- CSA Z462-18 – Workplace Electrical Safety

Companies now implement a variety of safety measures, including:

- Guidelines for safe working distances

- Personal protective equipment (PPE)

- Equipment labeling

- Arc flash studies

- Training

The Purpose of an Arc Flash Study

The safest way to perform maintenance work on electrical equipment is to turn it off beforehand. Unfortunately, this is not always possible, and work must sometimes be carried out on energized equipment.

An arc flash study is an engineered incident energy analysis. It determines safety protocol for qualified electrical personnel to work on equipment and circuit parts that must be kept energized.

The appropriate safety protocol is determined through standardized calculations. IEEE 1584 defines the process for the specification and performance of an arc-flash hazard calculation study.

More details are provided in IEEE P1584.1 – IEEE Draft Guide for the Specification of Scope and Deliverable Requirements for an Arc-Flash Hazard Calculation Study.

The guide outlines the minimum recommended requirements for an arc-flash hazard study, including scope of work and associated deliverables. The IEEE Guide provides techniques for design engineers and facility operators.

An arc flash study will:

- Identify the latest equations needed to find incident energy and the arc flash boundary

- Include the collection and analysis of field data

- Discuss and perform software simulation

It’s important for standards to be adhered to when determining the distance to which employees could be exposed to incident energy while working on or near electrical equipment. These are categorized as:

- Arc flash boundary: this is the distance where a worker without proper PPE would suffer second-degree burns

- Limited approach boundary: this distance is close enough to expose workers to a shock hazard; only trained and qualified workers should enter this space with proper PPE

- Restricted boundary: this area is closest to the exposed equipment and should only be entered by qualified workers with specialized training and proper PPE; work permits and documentation may also be required

You can see how important it is to have an up-to-date analysis for your facility. A miscalculation could lead to high-risk exposure and cause all sorts of damage.

Updated Arc Flash Calculations

The 1584-2018 – IEEE Guide for Performing Arc-Flash Hazard Calculations supersedes the IEEE 1584-2002 arc flash model.

The development of the 2018 edition spanned the better part of two decades. It’s based on thousands of hours of research, development, and validation.

Summarizing the Main Changes in IEEE 1584-2018

Following are the main enhancements of IEEE 1584-2018

- A new model based on over 1800 tests incorporates different electrode configurations

- By comparison, the original 2002 model was based on 300 tests

- Identification of five electrode configurations that may be present in the equipment being analyzed (VCB, VCBB, HCB, VOA, HOA)

- Improvements in the range of the gap for medium-voltage equipment, which has almost doubled since the 2002 edition

- Changes to the low system voltage range, which is now 208V through 600V

- Arc current model (0.208 kV to 0.6 kV): improved expected arc physical behavior, its increased sensitivity to gap variation, the correction of inconsistencies (such as cases when Ia > Ibf), etc.

- Arc current model (0.6 kV to 15 kV): the new model centers around the calculation of the arc current at three different voltages which are 600, 2700, and 14300 Volts AC

- An enhanced arc current variation correction factor determined from the median of the measured variation at each voltage level

- Revised low voltage arc sustainability limit

- Incident energy models include the additional three electrode configurations and apply the enclosure size-correction factor

- Updated arc-flash boundary model predicts shorter boundary distances

- The effect of grounding is no longer considered

With the latest standards and equations identified, the next step in the arc flash analysis study is to collect field data from your facility.

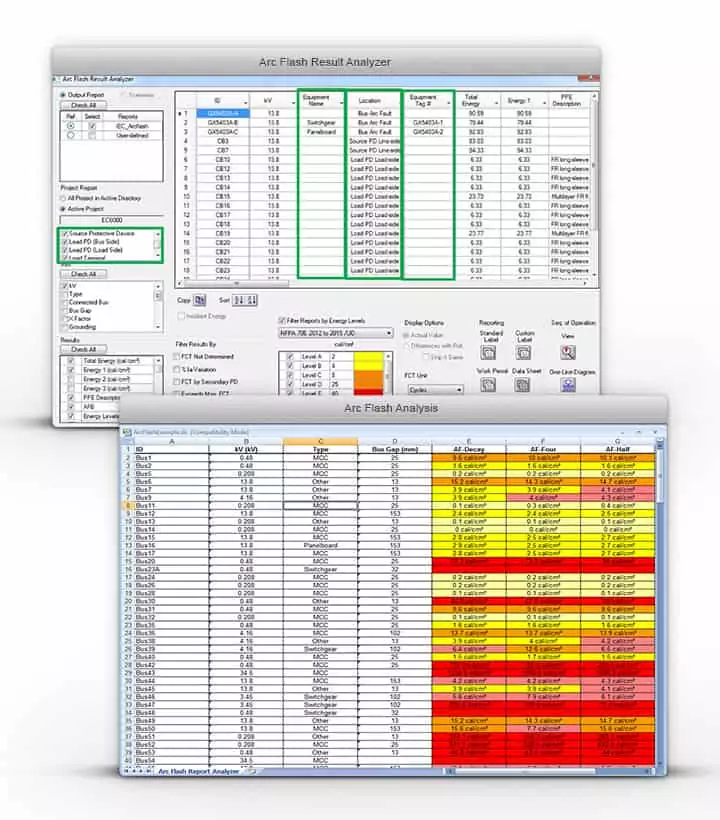

After that, specialized arc flash analysis software can be used to run simulations to form the basis of the discussion in your study.

PLEASE NOTE: not every software version will include the latest arc flash calculations.

Arc Flash Analysis Software

There are many benefits to using arc flash analysis software. As an integrated multi-disciplined engineering firm, we use ETAP Arc Flash Analysis Software v19.0.1 at Vista Projects.

The ETAP software includes IEEE-1584-2018 standards.

ETAP was an active participant in the development and validation of the new IEEE model. This participation ensures the correct application of the model in ETAP’s power system analysis software.

ETAP’s arc flash analysis software also allows us to:

- Automatically determine the arcing fault clearing time

- Instantly determine arc flash protection, restricted, & limited approach boundaries in compliance with NFPA 70E 2021

- Determine individual arcing current contributions

- Quickly run multiple arc flash calculations and analyze all of the different results

- Define customized arc flash parameters and arc specs or use system-calculated results to determine the arc flash energy

- Perform quick “what if” scenarios in your arc flash study

Ensure Arc Flash Safety & Compliance

Your facility and the safety of your workers may be at risk!

The incident energy analysis shall be updated when changes occur in the electrical distribution system that could affect the results of the analysis. The incident energy analysis shall also be reviewed for accuracy at intervals not to exceed 5 years.

This means that many facilities may not have conducted an arc flash study since the release of the IEEE 1584-2018 edition.

Our experienced electrical engineering group consists of professional engineers with experience designing and developing electrical and control systems. You can take advantage of our years of arc flash analysis experience.

Contact Vista today to conduct an arc flash study based on the latest IEEE standards. The new standards require more analysis than what was previously required and could help avoid downtime, prevent injuries, and save lives.

Arc Flash FAQ

What is an arc flash?

The term arc flash refers to the combined light and heat produced by an electrical explosion or arc fault. A voltage spike can occur in a matter of microseconds, but the arc duration is enough to carry thousands of amps.

The temperature of an arc flash can reach 35,000 degrees Fahrenheit. This is four times hotter than the estimated temperature on the surface of the sun.

What happens during an arc flash?

An arc flash is when the electric current flashes from its intended path and travels through the air from one conductor to another or to the ground. This is typically caused by an electrical bolt fault or short circuit.

As the current leaves its intended path and passes through the arc gap, it causes an ionization of the air. This creates the arc flash.

What’s the difference between an arc flash and an arc blast?

An arc fault causes the arc flash and arc blast. The flash consists of an explosive release of light and heat. The arc blast is the pressure wave created after an arc fault.

Arc blasts are powerful enough to damage equipment and throw adults to the ground. The blast can cause damage to your hearing or brain functions.

What causes an arc flash?

Many things can cause an arc flash:

- Dust and impurities on insulating surfaces

- Dropping tools and accidental touching can bring about a spark discharge

- Condensation of vapor and dripping water

- Insulating material failure

- Corrosion of equipment parts

- Faulty installation

- Equipment that isn’t designed for the use

Can arc flash kill you?

Yes, an arc flash can be deadly. As the arc flash travels through the air, anyone within close proximity to the source is at risk of serious injury. In the case of severe burning, an arc flash incident can be fatal.

What are the dangers of arc flash?

An arc flash can cause minor injuries, third-degree burns, and potentially death. Other injuries may include blindness, hearing loss, nerve damage, and cardiac arrest.

The danger of an electrical hazard is not just in the moment when it occurs but also afterwards. Skin could be severely burned for hours after contact was terminated if the current is directed into a person’s body or clothing.