Are you looking to breathe new life into your plant by upgrading its old wiring? It’s a critical move towards boosting operational efficiency, ensuring safety, and staying compliant with the latest electrical standards. Upgrading isn’t just about preventing risks like electrical fires or equipment failures; it’s about setting your facility up for future success.

Modern wiring systems support today’s tech-heavy operations more robustly, ensuring your machinery runs smoothly and safely. Plus, it’s a step towards sustainability, slashing energy consumption and operational costs. This article will guide you through the why, when, and how of upgrading your plant’s wiring, ensuring you’re equipped to make informed decisions every step of the way.

From assessing your current system to finalising the project with updated documentation, we’ve got you covered. Let’s dive in and explore how to turn this complex undertaking into a strategic advantage for your plant.

Why Upgrade Old Plant Wiring?

Upgrading old plant wiring is a critical step towards ensuring operational efficiency, safety, and compliance with current electrical standards. At the heart of this process is the goal to modernise facilities, thus enhancing their performance and extending their service life. Old wiring systems can pose significant risks, including electrical fires, equipment failures, and inefficiencies that can lead to increased energy consumption and operational costs.

Upgrading plant wiring, therefore, not only addresses the immediate concerns of safety and efficiency but also positions the facility for future growth and sustainability.

Safety Concerns

Upgrading old plant wiring significantly mitigates safety concerns by addressing two critical risks: the potential for electrical fires and the risk of electric shock. Outdated or deteriorated wiring can overheat or short-circuit, posing a serious fire hazard. Similarly, old wiring may not be properly insulated or grounded, increasing the risk of electric shock to personnel.

Prevent Electrical Fires

Improving the wiring system in a plant directly contributes to the prevention of electrical fires. By ensuring that all electrical circuits are properly installed and maintained, the risk of overheating and sparks that could ignite a fire is greatly reduced.

Reduce the Risk of Electric Shock

Upgrading to modern, safer electrical systems helps to reduce the risk of electric shock among workers. This involves the installation of proper grounding, circuit breakers, and other safety features that protect against accidental contact with live electrical components.

Efficiency Improvements

One of the primary benefits of upgrading plant wiring is efficiency improvements. By replacing old, inefficient wiring, plants can lower energy consumption, which not only reduces operating costs but also contributes to environmental sustainability. Additionally, improved machinery performance is achieved by ensuring that electrical systems provide reliable and adequate power for modern industrial operations.

Lower Energy Consumption

A direct consequence of upgrading plant wiring is the ability to lower energy consumption. Modern, efficient wiring reduces electrical losses and improves the overall energy efficiency of the plant, leading to significant cost savings and a lower carbon footprint.

Improve Machinery Performance

Improved machinery performance is another critical advantage of upgrading plant wiring. Reliable and efficient electrical supply ensures that machinery operates at optimal levels, reducing wear and tear and extending the lifespan of expensive equipment.

Compliance with Regulations

Ensuring compliance with regulations is a key driver for upgrading plant wiring. Adherence to the National Electrical Code (NEC) standards and local building codes is mandatory to maintain operational legality. The NEC standards are regularly updated to reflect the latest in electrical safety and efficiency practices, making compliance a moving target that requires periodic upgrades to wiring systems.

Meeting these standards not only ensures safety and efficiency but also protects plants from legal and financial penalties associated with non-compliance.

National Electrical Code (NEC) Standards

Compliance with NEC standards is essential for ensuring that electrical installations are safe and effective. The NEC provides guidelines for the safe installation of electrical wiring and equipment, which are crucial for preventing fires and electrical accidents in industrial settings.

Local Building Codes

In addition to NEC standards, upgrading plant wiring must also consider local building codes. These codes may have additional requirements that are specific to the location of the plant, ensuring that the electrical systems are suitable for the local environment and community standards.

When Should Plant Wiring Be Upgraded?

Plant wiring should be upgraded after a safety audit reveals potential risks or deficiencies in the current system. Additionally, when adding new machinery that demands more power or different specifications than the existing wiring can support, an upgrade becomes necessary. Generally, wiring systems should be reviewed and potentially upgraded every 20-25 years to ensure they meet current safety standards and operational requirements.

This timeline acknowledges the wear and tear on electrical systems over time and the evolution of technology and safety standards. Upgrading within this timeframe helps maintain a safe, efficient, and compliant industrial environment.

After a Safety Audit

Upgrade plant wiring after a safety audit identifies hazards or inefficiencies. This proactive approach ensures immediate action is taken to mitigate risks and enhance overall safety.

When Adding New Machinery

Initiate wiring upgrades when adding new machinery that requires more power or different specifications. This ensures the electrical system can adequately support new operational demands without compromising safety or efficiency.

Every 20-25 Years

Regularly assess and upgrade wiring systems every 20-25 years. This timeline reflects the need to stay aligned with advancements in technology, evolving safety standards, and the operational needs of modern industrial environments.

Who Should Perform the Wiring Upgrade?

Wiring upgrades should be performed by licensed electricians who specialise in industrial installations. These professionals possess the necessary expertise and experience to ensure that the upgrade meets all operational and safety standards. Industrial electrical contractors with a proven track record in plant upgrades are ideally suited for this task.

Their experience in navigating the complexities of industrial electrical systems ensures that the upgrade will enhance safety, efficiency, and compliance with all relevant regulations.

Licensed Electricians

Employ licensed electricians to ensure wiring upgrades are performed safely and in accordance with industry standards.

Specialising in Industrial Installations

Choose professionals specialising in industrial installations, guaranteeing they possess the specific knowledge required for plant environments.

Industrial Electrical Contractors

Opt for industrial electrical contractors renowned for their expertise and ability to navigate the complexities of industrial projects.

With Experience in Plant Upgrades

Prioritize contractors with experience in plant upgrades, as their proven track record offers invaluable insights and efficient solutions for modernizing electrical systems.

What are the Steps to Upgrade Old Plant Wiring?

Upgrading old plant wiring involves a systematic approach to ensure safety, efficiency, and compliance. Initially, assess the current wiring system to identify any damage, wear, or outdated components, and to evaluate its capacity and efficiency. Following this, plan the upgrade project by determining new wiring requirements based on current and future needs, and selecting appropriate materials and technologies.

Obtain necessary permits and approvals to ensure the project meets local and environmental regulations. The next step is to execute the wiring upgrade, which includes disconnecting old wiring, following safety protocols, and installing new wiring and components. After installation, test the new wiring system for compliance with standards, operational efficiency, and safety.

Finally, finalise the project by securing all installations and updating documentation and schematics, ensuring a successful upgrade to the plant’s electrical infrastructure.

Assess the Current Wiring System

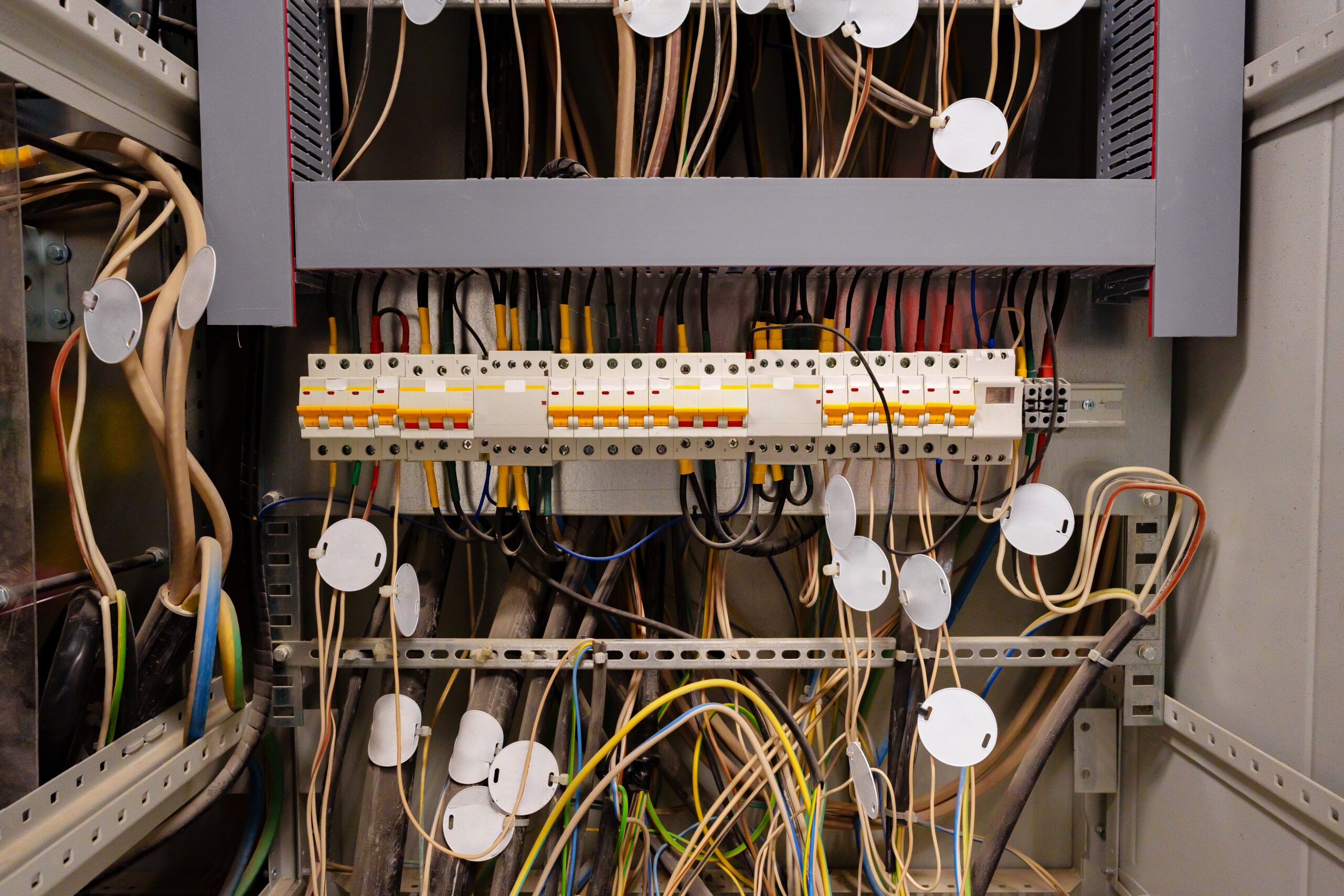

The initial step in upgrading plant wiring is to assess the current wiring system thoroughly. This involves inspecting for any damage or wear and identifying frayed wires or outdated components that could compromise safety or efficiency. Evaluating the system’s capacity and efficiency is crucial to understand if it meets the current load demands and energy efficiency levels.

This assessment forms the foundation for planning a comprehensive upgrade, ensuring the new system addresses all identified issues and is aligned with modern standards and operational requirements.

Inspect for Damage or Wear

Inspect the wiring system for any signs of damage or wear that could lead to safety hazards or inefficiencies, ensuring a thorough examination is conducted.

Look for Frayed Wires

Look closely to identify any frayed wires, which are critical fire risks and indicators of the urgent need for repair or replacement to maintain safety.

Check for Outdated Components

Check the system for outdated components that no longer comply with current standards or operational requirements, highlighting the need for modernisation in the upgrade process.

Evaluate Capacity and Efficiency

Evaluate the system’s capacity and efficiency to confirm it can handle current and future load requirements without compromising on performance or safety.

Assess Load Capacity

Assess the load capacity of the existing wiring to determine its adequacy in meeting the operational demands of the plant, pinpointing areas requiring enhancement.

Determine Energy Efficiency Levels

Determine the system’s energy efficiency levels to identify opportunities for reducing energy consumption and improving overall operational efficiency, aligning with sustainability goals.

Plan the Upgrade Project

After assessing the current wiring system, planning the upgrade project becomes the next critical step. This planning stage lays the groundwork for a successful upgrade, ensuring that all aspects of the project are aligned with the plant’s long-term goals and compliance requirements.

Determine New Wiring Requirements

Determine new wiring requirements, focusing on solutions that cater to both the current and future needs of the facility, ensuring scalability and adaptability.

Based on Current and Future Needs

Prioritise decisions based on current and future needs to accommodate evolving operational demands and technological advancements, securing long-term efficiency and growth.

Select Appropriate Materials and Technologies

Select appropriate materials and technologies that promise durability, safety, and compliance with the latest standards, forming the backbone of a robust electrical infrastructure.

High-Quality, Durable Wiring

Invest in high-quality, durable wiring to guarantee the longevity and reliability of the electrical system, significantly reducing maintenance requirements and downtime.

Energy-Efficient Lighting and Machinery

Embrace energy-efficient lighting and machinery within the upgrade to drive down energy consumption and operational costs while advancing the facility’s sustainability goals.

Obtain Necessary Permits and Approvals

Securing the necessary permits and approvals is a crucial step in the plant wiring upgrade process. This diligence supports the project’s integrity and contributes to its success by aligning with community standards and environmental stewardship.

Local Government Permits

Obtain local government permits to guarantee the wiring upgrade adheres to municipal regulations and safety standards, ensuring a legally compliant and smooth project execution.

Environmental Impact Assessments

Perform environmental impact assessments to identify and address any potential negative effects on the environment, underscoring a commitment to ecological sustainability and community health.

Execute the Wiring Upgrade

Executing the wiring upgrade involves a series of critical steps to ensure the project’s success. This execution phase transforms the initial plans into reality, significantly improving the plant’s electrical infrastructure.

Disconnect Old Wiring

Carefully disconnect old wiring, removing any outdated or compromised elements to make room for the upgrade.

Ensure Safety Protocols Are Followed

Throughout the project, ensure that all safety protocols are strictly adhered to to safeguard the well-being of all personnel.

Install New Wiring and Components

Progress to install new wiring and components, utilising cutting-edge materials and technologies to revitalise the facility’s electrical infrastructure.

Upgrade Panels and Circuits

Upgrade panels and circuits to not only meet but exceed current power needs, boosting the system’s reliability and safety.

Implement Energy-Efficient Solutions

Actively implement energy-efficient solutions such as adopting LED lighting and integrating high-efficiency motors, aiming to slash energy use and operational expenses.

Test the New Wiring System

After the installation phase, testing the new wiring system is crucial to ensure it meets all operational, safety, and compliance standards. This involves conducting load testing to verify the system’s capacity and resilience under operational demands. Additionally, measuring energy usage helps to confirm the efficiency gains from the upgrade.

Ensuring the system’s compliance with NEC and local codes is essential for legal and safety reasons. This testing phase is vital for validating the effectiveness of the upgrade and ensuring the plant’s electrical infrastructure is robust, efficient, and compliant with all relevant standards.

Ensure Compliance with Standards

Actively ensure compliance with standards, a critical step for upholding legal, safety, and operational integrity within the facility.

NEC and Local Codes

Strict adherence to NEC and local codes confirms the electrical system’s compliance with both national and municipal regulatory frameworks.

Verify Operational Efficiency

Verify operational efficiency through thorough evaluation, ensuring the system’s performance aligns with the plant’s productivity and sustainability objectives.

Conduct Load Testing

Conduct load testing to rigorously assess the electrical system’s ability to manage anticipated operational demands, reinforcing reliability and safety.

Measure Energy Usage

Measure energy usage to quantify the efficiency improvements post-upgrade, spotlighting reductions in operational expenses and environmental impact.

Finalise the Project

To finalise the project, it is imperative to secure all installations properly, using the correct fasteners and conduits to ensure the longevity and safety of the electrical system. The completion phase also involves updating documentation and schematics, including electrical diagrams, maintenance, and operation manuals. This step is crucial for maintaining an accurate record of the electrical infrastructure, facilitating future maintenance upgrades, and ensuring compliance with safety standards.

Finalising the project effectively consolidates the upgrade efforts, ensuring the plant’s electrical system is optimised for efficiency, safety, and regulatory compliance, ready for operational success.

Secure All Installations

Ensure that all installations are properly executed, maintaining the electrical system’s integrity and safety for enduring reliability.

Use of Proper Fasteners and Conduits

Emphasize the use of proper fasteners and conduits, critical for robust installations that withstand both physical and environmental challenges.

Update Documentation and Schematics

Update documentation and schematics to accurately reflect the upgraded system, providing a comprehensive reference for maintenance and compliance verification.

Electrical Diagrams

Maintain updated electrical diagrams that precisely map the current configuration of the electrical infrastructure, essential for effective troubleshooting and future enhancements.

Maintenance and Operation Manuals

Revise maintenance and operation manuals to incorporate new systems and equipment, guiding optimal performance and safety through proper operational practices.

Wiring the Future of Your Facility

Upgrading old plant wiring is more than a maintenance task, it’s a strategic investment in safety, efficiency, and long-term performance. From identifying outdated components to installing energy-efficient systems and securing final documentation, each step is key to modernising your operations. Done right, it sets the foundation for sustainable growth and smoother plant performance.

Vista Projects brings over three decades of industrial electrical expertise to every wiring upgrade, delivering fit-for-purpose solutions that enhance compliance, safety, and scalability.

Let’s upgrade your infrastructure the smart way, connect with Vista Projects to get started.