Welcome to our comprehensive guide on “How to Troubleshoot PLC Errors.” Programmable Logic Controllers (PLCs) are the backbone of industrial automation, but when errors occur, they can halt production and lead to significant downtime. This article is your go-to resource for identifying common PLC errors, understanding their root causes, and implementing effective troubleshooting strategies. Whether you’re dealing with hardware failures, software glitches, or operational mishaps, we’ve got you covered.

From diagnosing communication failures to reviewing PLC programs and ensuring your network communication is up to scratch, this guide will walk you through each step of the process. Plus, we’ll offer insights on implementing corrective actions and tips for preventing future errors. Whether you’re a seasoned engineer or new to PLC systems, this article will equip you with the knowledge to keep your automated systems running smoothly.

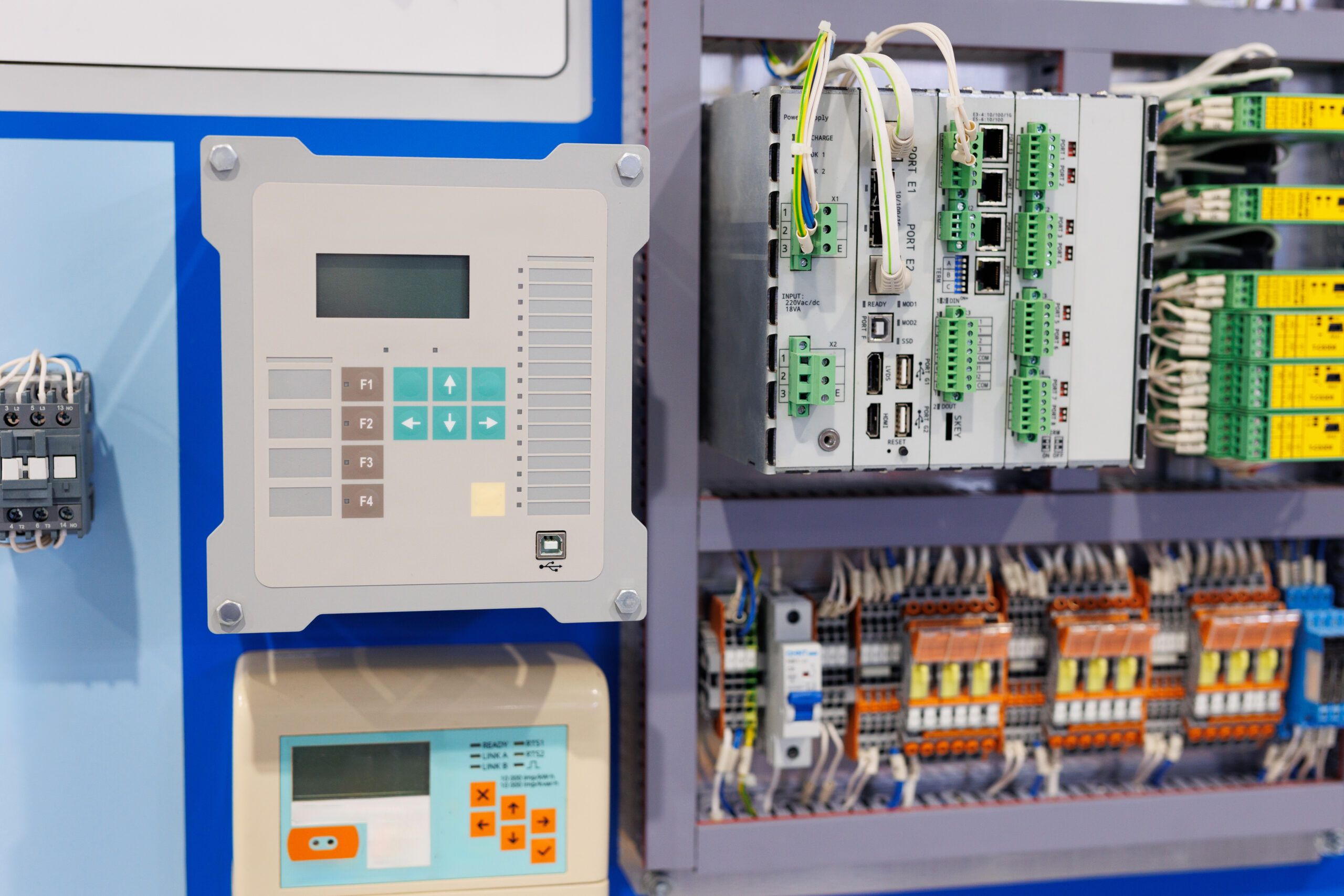

Identifying Common PLC Errors

Identifying common errors in Programmable Logic Controllers (PLCs) is crucial for ensuring the efficient operation of automated systems in industrial settings. The primary goal of diagnosing these errors is to minimise downtime, enhance system reliability, and optimise performance. Common PLC errors can generally be categorised into hardware failures, software issues, and operational errors.

Resolving issues requires a systemic approach, starting with the most common and easily identifiable problems before moving on to more complex scenarios. Effective troubleshooting can significantly reduce system downtime and prevent minor issues from escalating into major failures.

Communication Failures

Understanding and addressing communication failures is pivotal in maintaining the efficiency and reliability of PLC-based systems. These failures can stem from a variety of sources, including wired vs. wireless issues, protocol mismatches, and connection and signal errors. Applying the best industrial wiring practices helps minimise these risks by ensuring stable connections, reducing interference, and supporting long-term system reliability.

Identifying the root cause is the first step towards resolving these challenges and ensuring seamless communication within the system.

Wired vs. Wireless Issues

The debate between using wired and wireless communication systems introduces unique challenges. Wired connections offer reliability and security but can be plagued by connection and continuity errors. In contrast, wireless connections provide flexibility and reduce the need for extensive physical infrastructure, yet they are susceptible to interference and security concerns.

Protocol Mismatches

When devices within a PLC system communicate using incompatible protocols, protocol mismatches occur, leading to data being misinterpreted or lost. This discrepancy can cause system inefficiencies or malfunctions, highlighting the importance of protocol compatibility in system design.

I/O Module Failures

Failures in I/O modules can be differentiated into analog vs. digital module issues. Analogue modules are sensitive to voltage fluctuations, affecting their precision, whereas digital modules may misinterpret signals due to logic errors.

Both scenarios disrupt the data exchange between the PLC and machinery, impacting system performance.

Connection and Signal Errors

Connection and signal errors are often attributed to inadequate wiring, cable damage, or electromagnetic interference. These issues can result in data loss or erratic system behaviour, emphasising the need for meticulous cable management and proper shielding practices.

Processor Issues

PLC performance can be severely affected by processor issues, including overloading and memory errors. Processor overloading occurs when it is tasked beyond its capacity, and memory errors are a result of insufficient memory allocation for program requirements, both of which compromise the PLC’s operational efficiency.

Firmware Incompatibilities

Firmware incompatibilities arise with updates or modifications to the PLC’s firmware that do not align with existing hardware or software configurations, potentially causing system instability or crashes.

Power Supply Problems

Issues with the power supply, such as voltage fluctuations and connection and continuity errors, can lead to unpredictable system behaviour or damage to the PLC and connected devices. Ensuring a stable and uninterrupted power supply is crucial for the smooth operation of PLC systems.

Understanding PLC Error Codes

PLC error codes are crucial indicators that assist in pinpointing issues within an automation system. These codes, often manufacturer-specific, serve as a guide to understanding the nature of a problem, be it related to hardware, software, or communication failures. Deciphering these codes necessitates access to and familiarity with error code manuals or databases provided by the PLC manufacturer.

This expertise enables technicians and engineers to swiftly identify the root cause of an error, streamlining the troubleshooting process and facilitating prompt corrective actions. Effectively understanding and leveraging these error codes is essential for minimising system downtime and ensuring the seamless operation of industrial automation systems.

Deciphering Manufacturer-Specific Codes

Deciphering manufacturer-specific codes is essential for effective PLC troubleshooting. Each manufacturer employs a distinctive set of codes, necessitating a deep understanding of their unique syntax and semantics to diagnose issues accurately. Familiarity with these codes enables technicians to quickly identify the root cause of problems, whether they are related to hardware failures, software anomalies, or communication disruptions.

Mastery of the PLC’s language and access to comprehensive manufacturer documentation or digital resources are indispensable in this process.

Utilising Error Code Manuals

Effectively utilising error code manuals is crucial for swiftly resolving PLC errors. These manuals, curated by PLC manufacturers, offer exhaustive details on error codes, including their meanings and recommended remedial actions. Consulting these manuals allows technicians to apply precise solutions to address identified issues.

Keeping these manuals easily accessible and ensuring they are current is vital, as they serve as critical tools for safeguarding the operational efficiency of PLC systems.

Checking the PLC Hardware

Checking the PLC hardware is a critical step in troubleshooting and ensuring the integrity of industrial automation systems. This comprehensive evaluation is essential for identifying potential hardware issues that could lead to system failures, enabling timely interventions to prevent downtime and maintain operational continuity.

Inspect Wiring and Connections

Inspecting wiring and connections is a pivotal step in safeguarding the integrity of PLC systems. It is imperative to ensure all connections are both secure and intact to avert communication errors and potential system malfunctions.

Loose or Corroded Connections

Loose or corroded connections can critically undermine system performance. Proactively identifying and addressing these issues is essential for maintaining the reliability of PLC operations.

Broken Wires or Terminals

Broken wires or terminals pose a significant threat to electrical continuity, potentially leading to system failures. A meticulous inspection can uncover such problems, facilitating prompt repairs.

Verify Power Supply

Verifying the power supply encompasses checking for adequate voltage levels and a stable power source. These checks are indispensable for ensuring the PLC operates within safe parameters, safeguarding system stability and performance.

Adequate Voltage Levels

Maintaining voltage levels within manufacturer-specified ranges is critical to the health and operation of PLC components, protecting them from potential damage due to voltage anomalies.

Stable Power Source

A stable power source is crucial for the seamless operation of PLC systems. Power fluctuations can lead to unpredictable system behaviour or resets, underscoring the need for a reliable power supply.

Examine I/O Modules

Examining I/O modules for physical damage or wear and verifying proper module seating are essential practices for preventing data transmission errors and ensuring system reliability.

Physical Damage or Wear

Identifying physical damage or wear on I/O modules is vital for maintaining data integrity and optimal system performance. Regular checks facilitate early detection of such issues, averting potential system failures.

Proper Module Seating

Proper module seating is fundamental for ensuring effective connectivity and functionality within the PLC system. Confirming that all modules are accurately installed and securely connected enhances the system’s overall reliability.

Reviewing the PLC Program

Reviewing the PLC program is one of the basic PLC programming steps needed to ensure the optimal operation of automated systems. This crucial process involves a detailed examination of the program’s logic and structure to pinpoint any logic errors, incorrect configurations, or misconfigurations of timers and counters. It is vital to identify I/O addressing mistakes that could lead to operational inefficiencies or system failures.

This proactive approach not only facilitates troubleshooting of existing issues but also helps prevent potential problems, thereby reducing downtime and increasing operational efficiency.

Look for Logic Errors

Identifying logic errors is critical in ensuring the PLC program functions correctly. These errors can disrupt operational processes and lead to unintended outcomes.

Incorrect Ladder Logic

Incorrect ladder logic can result in unpredictable system behaviour. It is vital to ensure that each rung and logic gate accurately reflects the intended control logic to maintain process integrity.

Faulty Loop Conditions

Faulty loop conditions might cause processes to loop indefinitely or terminate unexpectedly. Precise definition of loop conditions is essential to avoid operational disruptions.

Check for Incorrect Configurations

Evaluating the program for incorrect configurations is crucial for system performance. Misconfigurations can adversely affect the system’s ability to perform as expected.

I/O Addressing Mistakes

I/O addressing mistakes can lead to incorrect data processing, with inputs or outputs being misdirected. Ensuring accurate I/O addressing is fundamental to system reliability.

Timer and Counter Misconfigurations

Timer and counter misconfigurations can interfere with the timing and sequence of operations. Correct configuration is necessary to ensure that processes execute in the proper order and for the appropriate duration.

Testing and Diagnosing the Network Communication

Testing and diagnosing network communication within PLC systems is crucial for ensuring uninterrupted data exchange between devices and control units. Through careful testing and diagnosis, potential communication challenges can be proactively addressed, significantly enhancing the reliability and efficiency of the PLC network.

Verify Network Cables and Connections

Ensuring the integrity and functionality of network cables and connections is crucial for the seamless operation of PLC systems. Regular inspections for physical damage and secure fittings are essential.

Cable Type and Quality

The cable type and quality play a significant role in network performance. Selecting the appropriate cables and ensuring their high quality are key factors in preventing data loss and minimising transmission errors.

Secure and Correct Connections

Maintaining secure and correct connections is vital for the stability of network communication. It is important to check that all connections are not only tightly secured but also correctly oriented to avoid connectivity issues.

Test Network Settings and Addresses

Conducting tests on network settings and addresses ensures that all devices within the network are properly configured and capable of efficient communication. This includes verifying that IP configurations are accurate and uniform across the network.

Correct IP Configuration

Having a correct IP configuration is essential for the smooth communication between devices on a network. Misconfigured IP settings can lead to communication failures and network disruptions.

Network Segment and Bandwidth Issues

Addressing network segment and bandwidth issues is crucial for preventing network congestion and ensuring that the network can adequately support the volume of data being transmitted, thus maintaining optimal system performance.

Implementing Corrective Actions

Implementing corrective actions is a crucial step in the PLC troubleshooting process, focusing on resolving identified issues to restore system functionality and reliability. This phase not only rectifies immediate issues but also aids in preventing future errors, enhancing the system’s overall resilience and performance.

Reset or Replace Faulty Components

Resetting or replacing faulty components is a critical step in rectifying PLC system issues, offering a path to swiftly reinstating system functionality.

Hard Reset Procedures

Hard reset procedures serve as a fundamental strategy for eliminating temporary errors and restoring the system to a default state, potentially resolving unforeseen glitches.

Identifying Components for Replacement

Identifying components for replacement is about pinpointing hardware failures and selecting the appropriate parts for repair or substitution, ensuring accuracy in the restoration process.

Update or Correct the PLC Program

Updating or correcting the PLC program is essential for fixing software-related problems. This includes applying logic fixes to eliminate errors in program execution and updating program versions for enhanced operation and compatibility.

Applying Logic Fixes

Applying logic fixes entails adjusting the control logic within the program to rectify errors, guaranteeing the system functions as designed.

Updating Program Versions

Updating program versions addresses existing bugs and integrates new functionalities, contributing to improved system performance and dependability.

Adjust Network Configurations

Adjusting network configurations is vital for improving device communication. This encompasses reconfiguring IP settings and network hardware adjustments to optimise network efficiency and consistency.

Reconfiguring IP Settings

Reconfiguring IP settings is crucial for ensuring seamless communication across the network solving issues like IP conflicts or misaligned subnet configurations.

Network Hardware Adjustments

Network hardware adjustments focus on enhancing or replacing network components to facilitate better data transmission and minimise communication errors, fostering a stable and robust network infrastructure.

Preventing Future PLC Errors

Preventing future PLC errors is key to ensuring the long-term efficiency and reliability of industrial automation systems. Implementing strategies to improve production using advanced controls not only augments the workforce’s capabilities but also cultivates a culture of continuous improvement and proactive vigilance. This approach establishes a solid foundation for error prevention while enhancing overall system resilience.

Regular Maintenance Checks

Regular maintenance checks are pivotal for the early identification and correction of potential issues, ensuring uninterrupted PLC system operation.

Scheduled Inspections

Scheduled inspections offer a structured approach to assessing the system’s condition, pinpointing wear and potential faults before they become critical.

Cleaning and Environmental Controls

Implementing cleaning and environmental controls is crucial for preserving the PLC’s operational environment preventing issues related to dust and temperature fluctuations.

Update Software and Firmware

Regular updates to software and firmware are essential for maintaining system security and functionality, aligning the PLC with the latest technological advancements.

Keeping Up with Manufacturer Updates

Staying abreast of manufacturer updates guarantees access to the newest fixes and features, protecting the system against known vulnerabilities.

Compatibility Checks

Performing compatibility checks before integrating new hardware or software is key to ensuring smooth system operations and avoiding conflicts.

Training for Personnel

Investing in training for personnel on current operational practices and system updates is crucial for optimising system performance and reliability.

Operational Training

Providing operational training equips staff with the skills needed for effective management and operation of the PLC system, boosting productivity.

Troubleshooting and Maintenance Courses

Offering troubleshooting and maintenance courses arms personnel with the expertise to swiftly identify and fix issues, minimising downtime and sustaining system integrity.

Keeping Your Automation Future-Ready

Ensuring your PLC systems run smoothly isn’t just about fixing issues, it’s about building resilience in your operations. From identifying common errors to maintaining robust network communication and refining your PLC programming, proactive troubleshooting safeguards productivity and reduces costly downtime.

At Vista Projects, your trusted engineering experts, our integrated approach to engineering and system integration means we not only understand PLCs but also optimise them. With decades of experience across diverse industries, we’re here to support your automation journey from problem to performance.

Ready to reduce errors and unlock smarter automation? Let’s connect and troubleshoot your next big success.